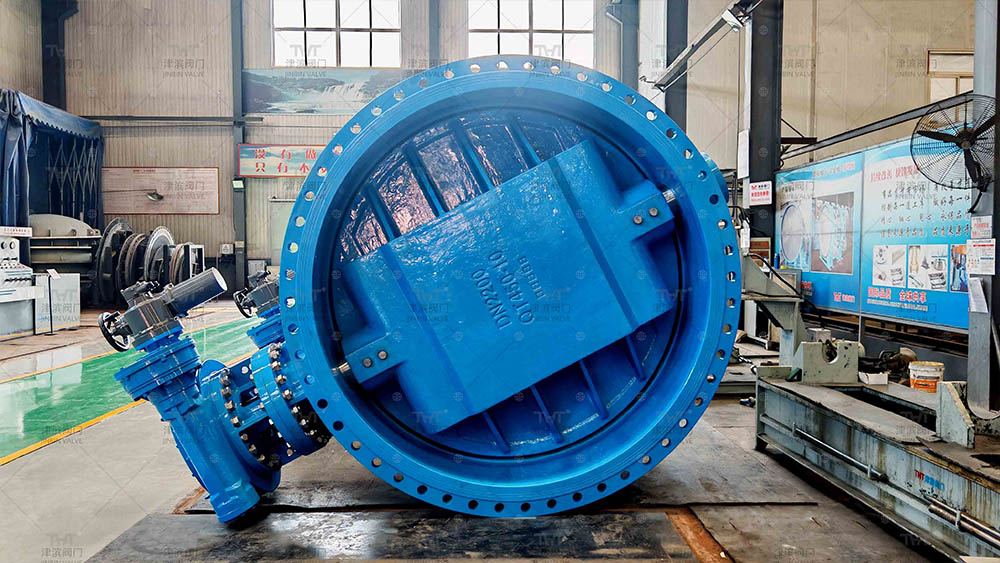

In the Jinbin workshop, five large-diameter double eccentric butterfly valves have been inspected. Their dimensions are DN2200, and the valve bodies are made of ductile iron. Each butterfly valve is equipped with an electric actuator. At present, these several butterfly valves have been inspected and accepted, and are waiting for packaging and shipment.

Unlike traditional concentric butterfly valves (where the valve stem coincides with the center of the butterfly plate and the valve body) or single eccentric flanged butterfly valve (where only the valve stem deviates from the center of the butterfly plate), double eccentric butterfly valves adopt a double eccentric design of “the valve stem axis deviating from the center of the butterfly plate + the valve stem axis deviating from the center of the valve body”.

This structure enables the butterfly plate to only come into contact with the valve seat when it is close to closing during the opening and closing process. During the rest of the stroke, the butterfly plate is completely separated from the valve seat, significantly reducing the friction and wear of the sealing surface. Especially in large-diameter scenarios, it can avoid the “hard friction” on the sealing surface caused by the self-weight of the butterfly plate or the medium pressure, significantly extending the service life of the sealing pair, which is usually more than 30% longer than that of single ductile iron butterfly valves.

The butterfly plate of the large-diameter electric butterfly valve adopts a streamlined design. When fully open, the butterfly plate has a small blocking area for the medium and a low flow resistance coefficient, which can reduce the energy loss of the pipeline system. For large-flow pipelines with a diameter of DN1000 or more (such as urban water supply trunk lines and power plant circulating water systems), the energy consumption of the pump set has been greatly saved.

The valve body material can be selected from ductile iron (for municipal water), carbon steel (for industrial oil), or stainless steel (for corrosive media) based on the characteristics of the medium. The surface of the butterfly plate can be spray-welded with a wear-resistant layer (such as tungsten carbide), which can withstand the erosion of media containing a small amount of particles (such as sand and slag). For conveying fluids containing impurities such as sewage and ash slurry, its service life is 2 to 3 times that of ordinary butterfly valves.

The large-diameter double eccentric butterfly valve, through structural innovation, has balanced the flow control, sealing performance and operational life of large-diameter pipelines. It has become an efficient solution to replace traditional gate valves and ball valves in high-flow and complex medium systems in municipal, power, water conservancy, industrial and other fields. It is especially suitable for long-term operation scenarios that are sensitive to energy consumption and maintenance costs.

Post time: Jul-25-2025