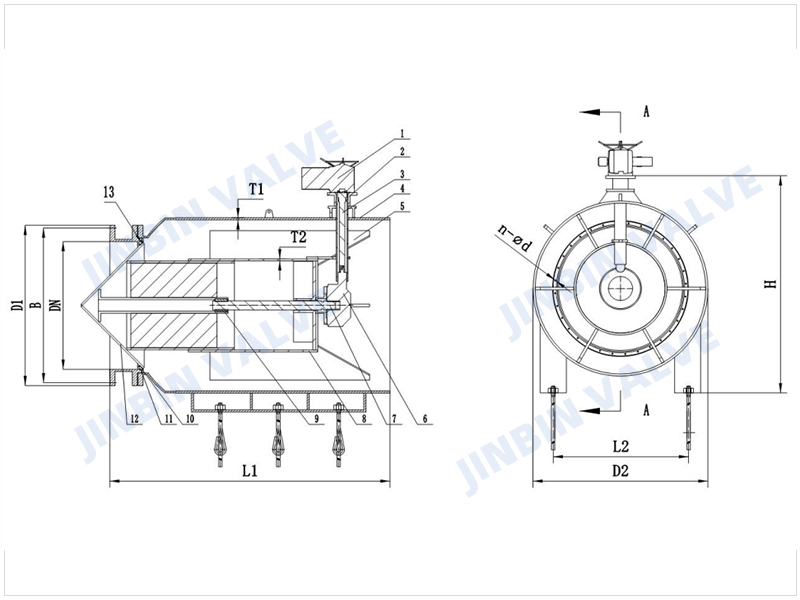

Hollow jet valve DN1500

Hollow Jet Valve

The hollow jet valve is a type of valve used in fluid control systems. This valve is designed with a hollow or cavity in its center, allowing a fluid to pass through it.

The hollow jet valve is a type of valve used in fluid control systems. This valve is designed with a hollow or cavity in its center, allowing a fluid to pass through it. It is commonly used in applications where high velocity and direction control of the fluid are important. The hollow jet valve typically consists of a body with an inlet and outlet, and a movable orifice or disc that controls the flow of the fluid. When the valve is in the closed position, the orifice blocks the fluid flow. As the valve is opened by moving the orifice away from the seat, the fluid can pass through the hollow center and exit through the outlet.

Hollow jet valves are often used in water dam, and power generation. They are particularly useful in controlling high-pressure or high-velocity fluid flows, where precise control and efficient operation are necessary. The design and materials used in hollow jet valves can vary depending on the specific application and the type of fluid being controlled. Factors such as pressure, temperature, and chemical compatibility need to be considered when selecting a hollow jet valve for a particular system. Regular maintenance and inspection are important to ensure the proper functioning of these valves and prevent any leakage or failure.

Our hollow-jet valves have proved their high efficiency in hydroelectric power plants and irrigation dams. They ensure a regulated and environmentally compatible outlet of water either to the outside or into underwater tanks. The water is also enriched with oxygen at the same time. The high-quality steel construction of the hollow-jet valves combined with elastic/metallic sealing enables energy dissipation without cavitation.

-Design Features-

◆In dam application, control valves such as Hollow jet valves are installed after the butterfly valves on the outlet side. These valves always work as flow regulating or control valves. Hallow jet valves designed to perform regulating or control.

◆function in water supply system without any vibration as much as valve opening.

-Advantages-

◆Accurate adjustment

◆No cavitation

◆No vibration

◆Manual operating needs less force. Regardless of piston situation, force required to move the piston extreme of thoroughly open and closed are the same.

◆Because of discharging to air no cause of turbulence and no need to install anti water hammer in downstream.

◆Easy maintenance

●Driving manger:Manual-operated/Electric-actuated

●Flange ends: EN1092-1 PN10/16,ASME B16.5

●Test & inspection: EN12266,ISO5208D

●Fluid Media: Water

●Working Temp.: ≤70℃

●Main Parts and Material

| No | Description | Material |

| 1 | Electric actuator | Assembly |

| 2 | Yoke | Carbon steel |

| 3 | Shaft | ASTM SS420 |

| 4 | Body | Carbon steel |

| 5 | Re-forcing rib | Carbon steel |

| 6 | Bevel gear | Assembly |

| 7 | Driving shaft | SS420 |

| 8 | Shutter body | Carbon steel |

| 9 | Nut | Al.Bz or Brass |

| 10 | Retaining ring | Carbon steel or stainless steel |

| 11 | Shutter seal ring | NBR/EPDM/SS304+Graphite |

| 12 | Shutter cone | Carbon steel |

| 13 | Body seat ring | Welded stainless steel |

●Dimensional Data

| DN(mm) | L1(mm) | D1(mm) | B(mm) | d | n | D2(mm) | L2(mm) | Wgt(kg) |

| 400 | 950 | 565 | 515 | M24 | 16 | 580 | 490 | 1460 |

| 600 | 1250 | 780 | 725 | M27 | 20 | 870 | 735 | 2320 |

| 800 | 1650 | 1015 | 950 | M30 | 24 | 1160 | 980 | 3330 |

| 1000 | 2050 | 1230 | 1160 | M33 | 28 | 1450 | 1225 | 4540 |

| 1200 | 2450 | 1455 | 1380 | M36 | 32 | 1740 | 1470 | 6000 |

| 1500 | 3050 | 1795 | 1705 | M45 | 40 | 2175 | 1840 | 8700 |

| 1800 | 3650 | 2115 | 2020 | M45 | 44 | 2610 | 2210 | 1230 |