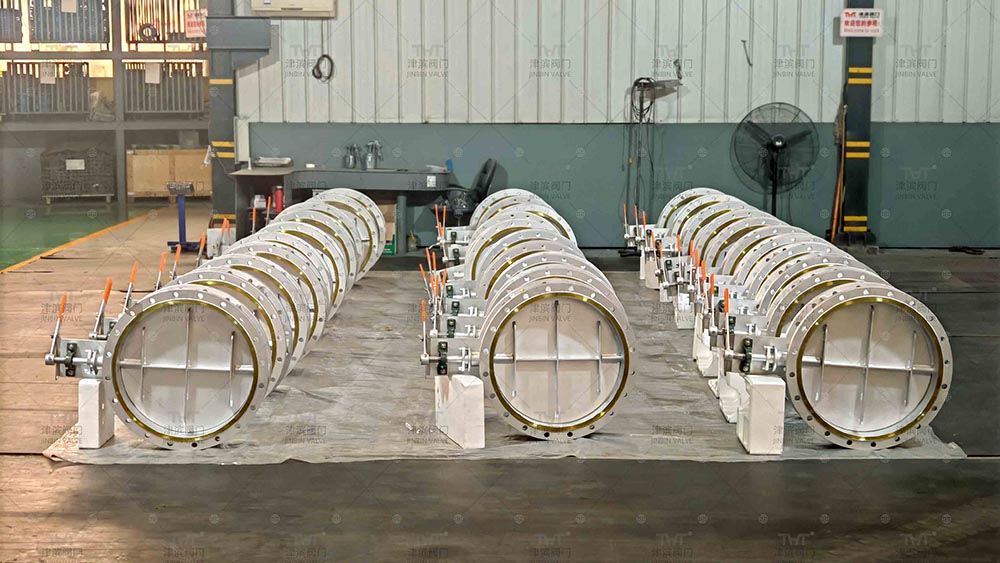

Recently, the factory has completed the production of 31 manual damper valves. From cutting to welding, the workers have carried out meticulous grinding. After quality inspection, they are now about to be packaged and dispatched.

The size of this air damper valve is DN600, with a working pressure of PN1. They are made of Q345E carbon steel and are equipped with handle control switches. The manual air valve core with a handle is used in ventilation systems to manually adjust air volume and open/close air ducts. With its simple structure, low cost and no need for power supply, it is widely applied in civil, industrial, fire protection and other scenarios.

In the industrial field, damper valve mostly used in the ventilation systems of mechanical processing, welding workshops, etc., for local exhaust or supply air branch control. Workers can quickly adjust the opening degree of the refractory damper through the handle according to the welding volume, equipment heating degree and other work intensity, ensuring that harmful smoke or heat is discharged in time. Meanwhile, its mechanical structure can adapt to complex environments such as dust and oil stains in the workshop. It is more wear-resistant than electric air dampers and suitable for frequent manual adjustment.

In the fire smoke exhaust system, it is an important auxiliary control component that complies with fire protection regulations. It is often installed at the branch points of smoke exhaust ducts or the boundaries of fire compartments. Under normal circumstances, the smoke exhaust volume can be manually adjusted. In case of fire, if the electric control fails, personnel can close the specific area flue gas damper through the handle to prevent smoke from entering, or open the key smoke exhaust path. Some special models are also equipped with locking devices Avoid misoperation in case of fire.

In addition, manual air valves are also commonly used in laboratory fume hoods, small fresh air units and other equipment. Manual air valves are installed on the exhaust branch pipes of fume hoods in the laboratory. Laboratory personnel can fine-tune the air volume according to the amount of harmful gases to maintain the negative pressure inside the cabinet. The adjustment accuracy is more intuitive than that of electric valves. It can be used at the air intake end of household fresh air purifiers and commercial air curtains to adjust the air volume, which can also reduce equipment costs and simplify operation.

Post time: Oct-31-2025