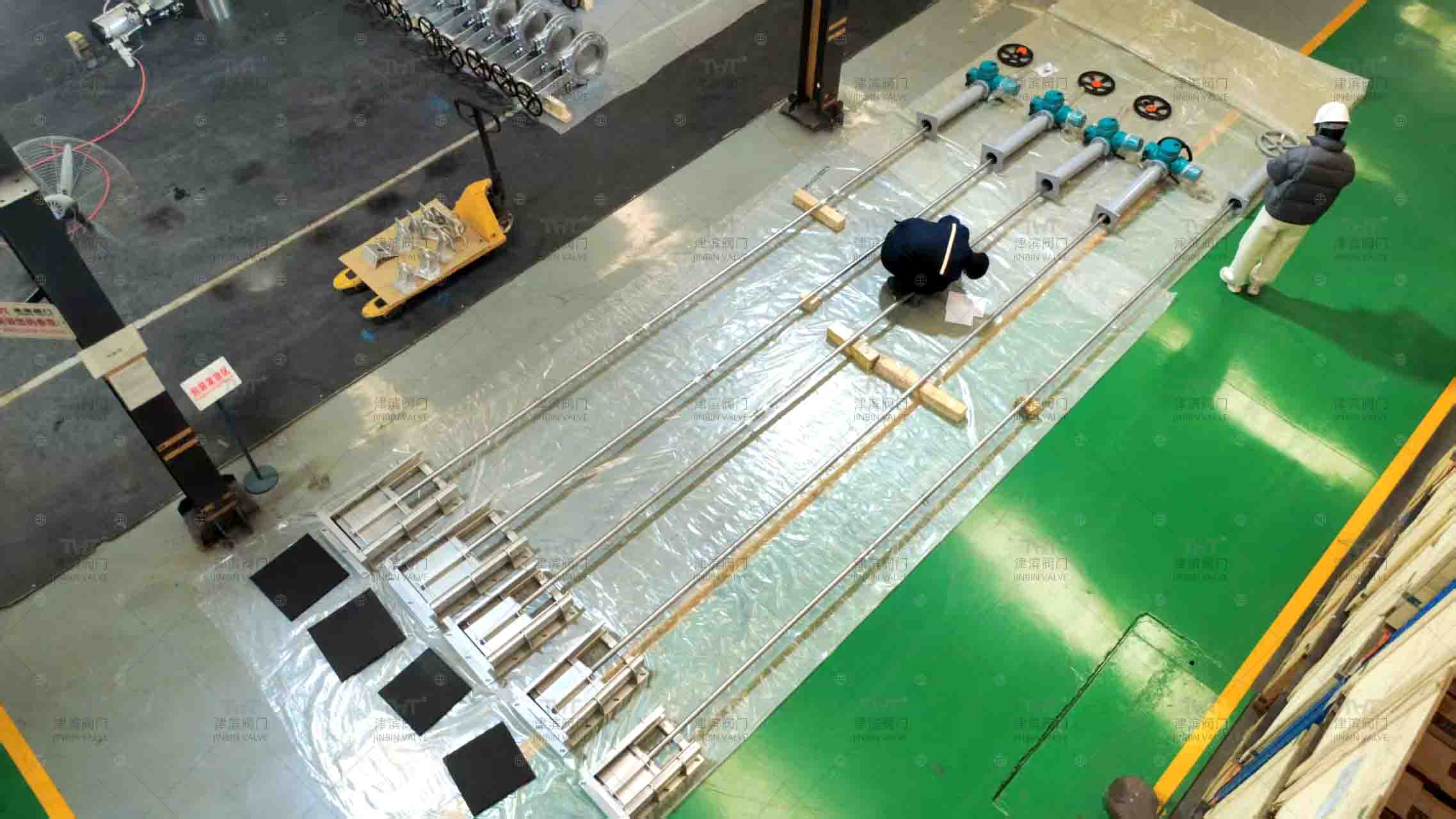

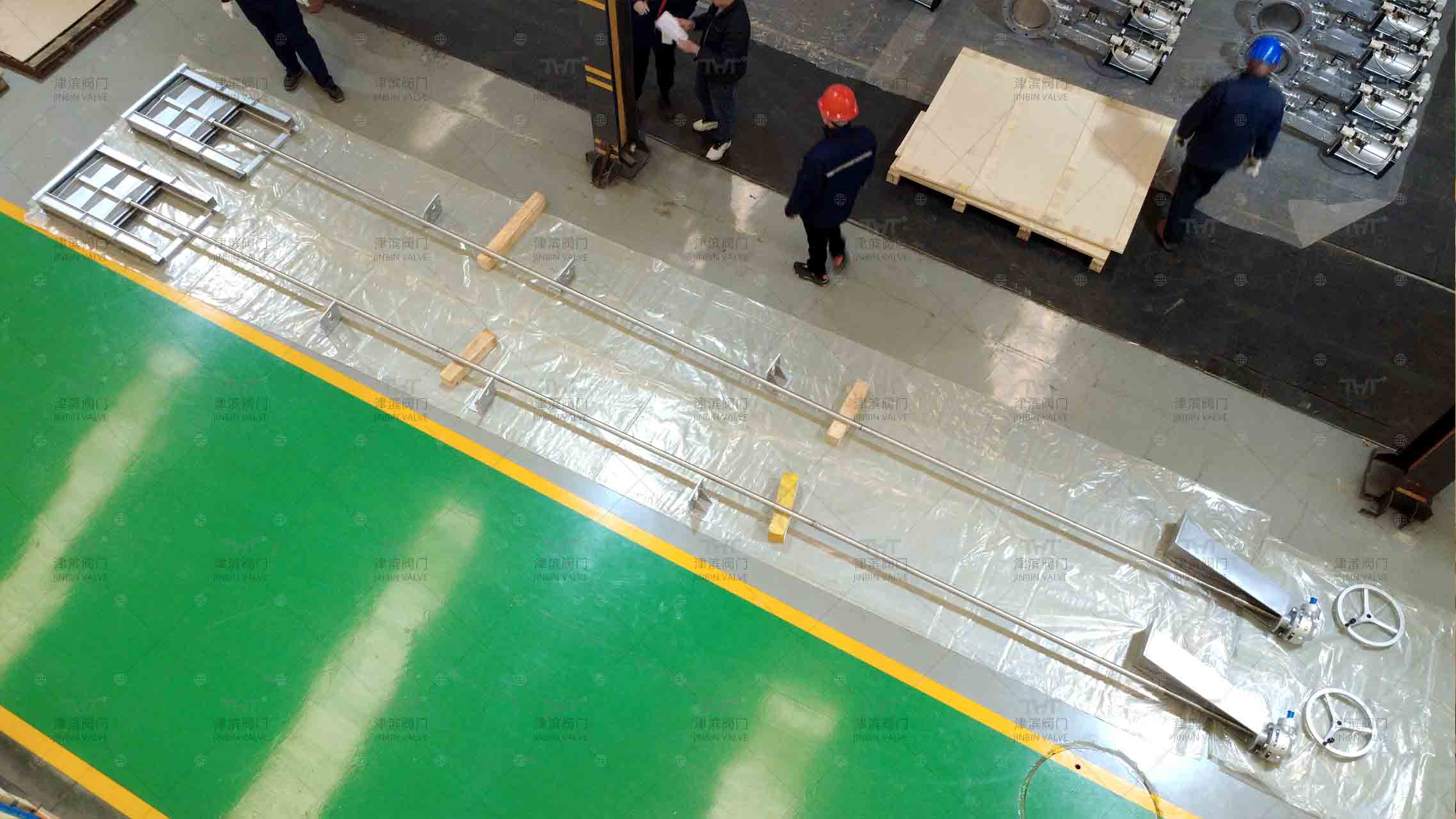

In the Jinbin Valve Factory, workers are conducting the final inspection and confirmation on a batch of stainless steel gates, which are about to be sent to the United Arab Emirates. The wall penstock gate dimensions are specified by the customer, namely 350×350, 300×300, and 250×250. It adopts a long-pole structure and is equipped with both electric and manual devices. Each interface has been carefully labeled by workers for on-site installation.

Compared with common material penstock gates such as cast iron and carbon steel, stainless steel 316 material gates have significant advantages in terms of corrosion resistance, service life, and applicable scenarios, which are specifically reflected in the following four points:

A. Super corrosion resistance, suitable for harsh working conditions

316 stainless steel contains molybdenum and has a much higher tolerance to chloride ions than 304 stainless steel and ordinary carbon steel. It can resist the erosion of seawater, acid and alkali solutions, and chemical media. In coastal, chemical, and sewage treatment scenarios, it will not have the rusting and perforation problems of ordinary gates, significantly reducing the risk of corrosion and leakage.

B. It has excellent mechanical properties and strong structural stability

316 stainless steel combines high strength and toughness. Its impact resistance and deformation resistance are superior to those of cast iron gates. It is less likely to deform or break under the impact of high-pressure and high-flow media. Moreover, the material density is uniform, and the resistance to opening and closing when the penstock gate is in operation is small, which can reduce the energy consumption and wear of the opening and closing equipment.

C. Low maintenance cost and longer service life

Ordinary carbon steel gates need regular rust removal and painting maintenance; otherwise, they are prone to rapid aging. In contrast, 316 stainless steel gates have a smooth surface and are less likely to accumulate dirt and microorganisms. They only require simple cleaning on a daily basis and do not need frequent anti-corrosion treatment. Their service life can be 2 to 3 times that of ordinary gates, and they offer better cost performance in the long run.

D. Hygiene performance meets standards and is suitable for special fields

316 stainless steel is a food-grade material with no risk of heavy metal leaching. It can be used in scenarios with high requirements for medium purity, such as drinking water treatment and pharmaceutical and chemical industries. In contrast, ordinary cast iron gates are prone to rust and contamination of the medium and cannot meet hygiene standards.

Therefore, although the initial purchase cost of stainless steel 316 wall mounted penstock valve is slightly higher, they are more suitable for complex and harsh working conditions due to their corrosion resistance, durability and easy maintenance. Jinbin Valve specializes in manufacturing stainless steel penstocks, which are supplied to water conservancy projects in Asia, Africa, Europe, America and other countries. We have been recognized by many customers. If you also have related needs, please leave a message below and you will receive a reply within 24 hours!

Post time: Dec-22-2025