Recently, an important customer delegation from Thailand visited the Jinbin Valve Factory for an inspection. This inspection focused on high-pressure goggle valve, aiming to seek opportunities for in-depth cooperation. The relevant person in charge and technical team of Jinbin Valve warmly received them.

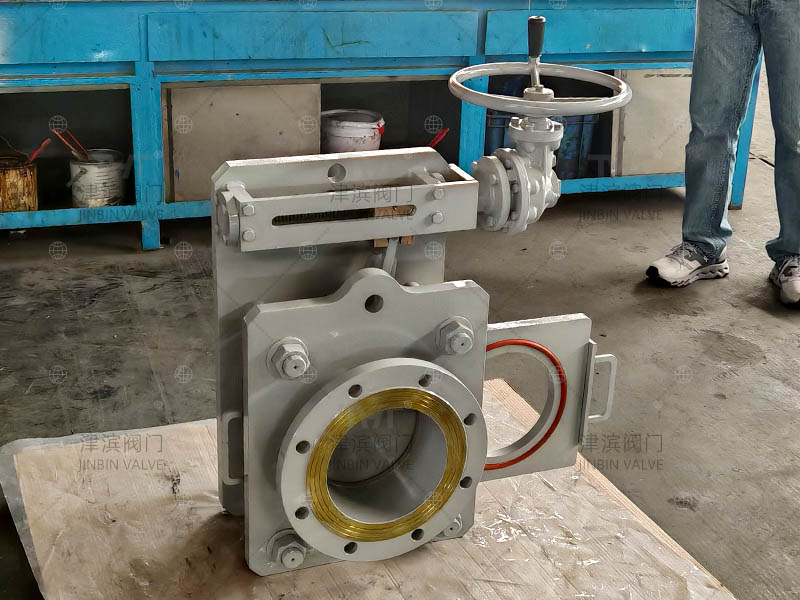

Accompanied throughout by technicians, the Thai client visited the factory’s production workshop, R&D center and quality inspection department in depth, conducting a detailed inspection of the production process, technical techniques and quality control system of high-pressure sliding plate goggle valve. During the visit, the customer showed great interest in the core technical parameters of the high-pressure line blind valve, such as its structural design, sealing performance and pressure resistance strength, and raised many professional questions.

The technical advisors of Jinbin Valves, relying on their solid professional knowledge and rich practical experience, provided comprehensive and in-depth answers to the customers’ questions in combination with on-site equipment and cases. Professional explanations and intuitive demonstrations enabled the customers to have a clearer understanding of the high-pressure blind plate valve. They also highly recognized the technical strength of Jinbin Valve, clearly stating that they had gained a lot from this visit and were full of expectations for future cooperation.

High-pressure goggle valves, as indispensable key equipment in industrial pipeline systems, have many significant advantages. It adopts a unique sealing structure design, which can achieve efficient and reliable sealing in harsh environments such as high pressure, high temperature and strong corrosion, effectively preventing medium leakage and ensuring production safety. The material of the valve has undergone strict screening and special treatment, featuring excellent wear resistance and corrosion resistance, which greatly extends its service life and reduces the maintenance costs of enterprises. The operation mode is flexible and diverse. It can be operated manually or equipped with electric, pneumatic and other drive devices as needed to meet the usage requirements under different working conditions. The operation is convenient and efficient.

Among numerous application scenarios, high-pressure blind plate valves are particularly widely used in the petrochemical industry. When conducting maintenance, renovation or troubleshooting of pipeline systems in petrochemical enterprises, it is necessary to isolate specific pipelines to ensure the safety of the operators. At this point, the high-pressure blind plate valve can quickly and reliably cut off the medium flow, isolate the area to be maintained from other operating systems, and create a safe environment for maintenance work. Jinbin Valve’s high-pressure blind plate valve, with its outstanding performance, has accumulated a good reputation in the petrochemical industry and has become the trusted choice of many enterprises.

The visit and inspection by the Thai client this time not only deepened the mutual understanding between the two sides but also laid a solid foundation for future cooperation. Jinbin Valves will also take this as an opportunity to continuously innovate, constantly improve product quality and service levels, expand the international market, and provide global customers with more high-quality valve solutions.

Post time: May-06-2025