1. Ukufakwa kwesango le-Penstock:

(1)Esangweni lensimbi elifakwe ngaphandle kwembobo, indawo yesango ivamise ukushiselwa ngepuleti lensimbi elishumekiwe elizungeze imbobo yodonga lwechibi ukuze kuqinisekiswe ukuthi indawo yesango ihambisana nentambo yokumisa amanzi ngokuchezuka okungaphansi kuka-1/500.

(2) Ngesango lensimbi elifakwe esiteshini, faka i-slot yesango endaweni ebekiwe, lungisa indawo ukuze umugqa ophakathi nendawo uhambisane nentambo yokumisa amanzi, ukuchezuka kungabi ngaphezu kwe-1 / 500, futhi iphutha elikhulayo lezingxenye ezingaphezulu nezingaphansi zingaphansi kuka-5mm. Ngemuva kwalokho, ishiselwa ngokuqiniswa okugodliwe (noma ipuleti elishumekiwe) futhi ihlulwe kabili.

2. Ukufakwa komzimba wesango: phakamisa umzimba wesango endaweni bese uwufaka endaweni yokukhala yesango, ukuze ugcine igebe phakathi kwezinhlangothi zombili zesango kanye nembobo yesango ngokuyisisekelo ilingana.

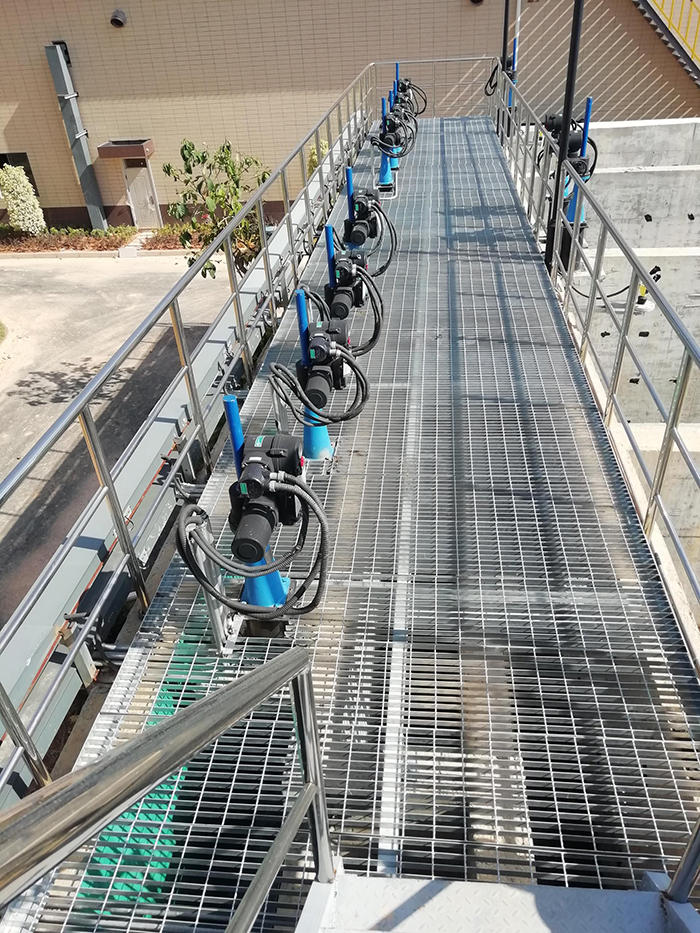

3. Ukufakwa kwe-hoist kanye nokusekelwa kwayo: lungisa indawo ye-hoist frame, gcina isikhungo sohlaka siqondane nesikhungo sesango lensimbi, phakamisa i-hoist endaweni, xhuma isiphetho senduku yesikulufu nesigxobo sokuphakamisa wesango nge-pin shaft, gcina umugqa ophakathi wenduku yesikulufa uhambisane nomugqa ophakathi wesango, i-plumb ngeke ibekezelelane ngaphezu kwalokho / kungabi ngaphezu kuka-2 mm. Okokugcina, i-hoist kanye nebakaki kuhlanganiswe nama-bolts noma ama-welding. Ukuze isango lensimbi livulwe futhi livalwe umshini wokubamba, kudingekile kuphela ukuqinisekisa ukuthi indawo yokuphakamisa yomshini wokubamba kanye nesikhwama sokuphakamisa isango lensimbi kusendizeni efanayo eqondile. Lapho isango lensimbi lehliswa futhi libanjwa, lingakwazi ukushelela ku-slot yesango ngokushelela eduze kwe-slot yesango, futhi inqubo yokubamba nokuwisa ingaqedwa ngokuzenzakalelayo ngaphandle kokulungiswa ngesandla.

4. Uma i-hoist kagesi isetshenziswa, ukunikezwa kwamandla kuzoxhunywa ukuze kuqinisekiswe ukuthi isiqondiso sokuzungeza senjini sihambisana nomklamo.

5. Vula futhi uvale isango lensimbi izikhathi ezintathu ngaphandle kwamanzi, hlola ukuthi kukhona yini isimo esingavamile, ukuthi ukuvulwa nokuvala kuyaguquguquka, futhi ulungise uma kunesidingo.

6.Ukuhlola okuvulekile nokuvalayo kwenziwa ngaphansi kwengcindezi yamanzi eklanyelwe ukubona ukuthi i-hoist ingasebenza ngokujwayelekile yini.

7. Hlola uphawu lwesango le-sluice. Uma kukhona ukuvuza okungathi sína, lungisa izisetshenziswa zokucindezela ezinhlangothini zombili zohlaka kuze kube yilapho kufinyelelwa umphumela owufunayo wokuvala.

8. Ngesikhathi sokufakwa kwesango le-sluice, indawo yokubeka uphawu kufanele ivikelwe emonakalweni.

Isikhathi sokuthumela: May-21-2021