1. Installation of Penstock gate:

(1)For the steel gate installed on the outside of the hole, the gate slot is generally welded with the embedded steel plate around the hole of the pool wall to ensure that the gate slot coincides with the plumb line with a deviation of less than 1 / 500.

(2) For the steel gate installed in the channel, insert the gate slot into the reserved slot, adjust the position so that the center line coincides with the plumb line, the deviation is not more than 1 / 500, and the cumulative error of upper and lower parts is less than 5mm. Then, it is welded with the reserved reinforcement (or embedded plate) and grouted twice.

2. Installation of gate body: hoist the gate body in place and insert it into the gate slot, so as to keep the gap between both sides of the gate and the gate slot basically equal.

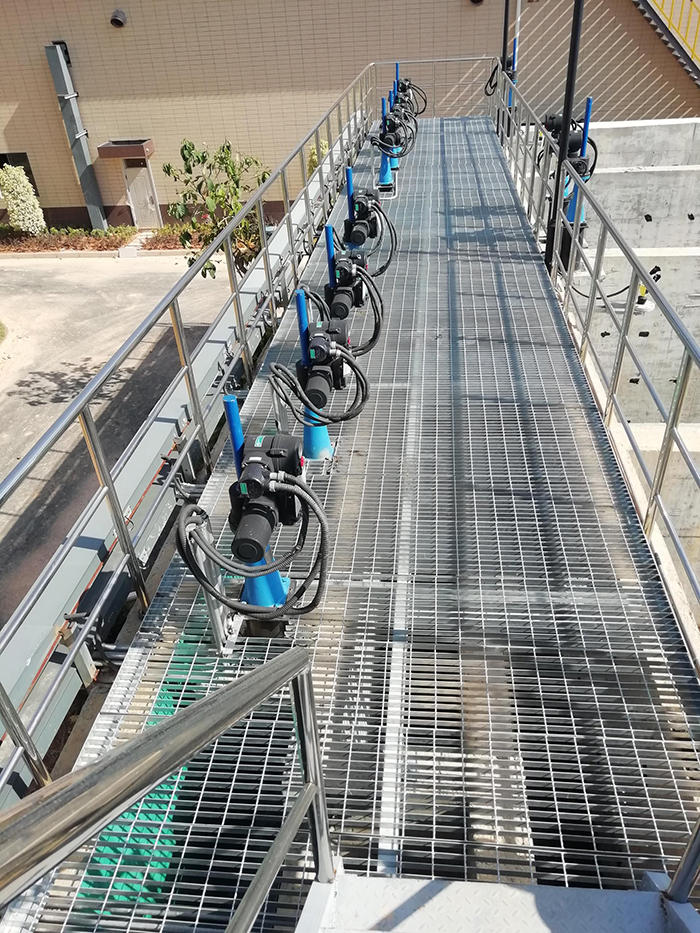

3. Installation of hoist and its support: adjust the position of the hoist frame, keep the center of the frame coincide with the center of the steel gate, hoist the hoist in place, connect the end of the screw rod with the lifting lug of the gate with the pin shaft, keep the center line of the screw rod coincide with the center line of the gate, the plumb tolerance shall be no more than 1 / 1000, and the cumulative error shall be no more than 2mm. Finally, the hoist and bracket are fixed with bolts or welding. For the steel gate opened and closed by the grab mechanism, it is only necessary to ensure that the lifting point of the grab mechanism and the lifting lug of the steel gate are in the same vertical plane. When the steel gate is lowered and grasped, it can slide into the gate slot smoothly along the gate slot, and the grabbing and dropping process can be completed automatically without manual adjustment.

4. When the electric hoist is operated, the power supply shall be connected to ensure that the rotation direction of the motor is consistent with the design.

5. Open and close the steel gate three times without water, check whether there is any abnormal condition, whether the opening and closing is flexible, and adjust if necessary.

6.Open and close test is carried out under the designed water pressure to observe whether the hoist can work normally.

7. Check the seal of the sluice gate. If there is serious leakage, adjust the pressing devices on both sides of the frame until the desired sealing effect is achieved.

8. During the installation of the sluice gate, the sealing surface should be protected from damage.

Post time: May-21-2021