I-valve yejet engenalutho DN1500

I-Hollow Jet Valve

I-valve ye-jet engenalutho iwuhlobo lwe-valve esetshenziswa ezinhlelweni zokulawula uketshezi. Le valve yakhiwe ibe nembobo noma imbobo phakathi nendawo, evumela uketshezi ukuba ludlule kuyo.

I-valve ye-jet engenalutho iwuhlobo lwe-valve esetshenziswa ezinhlelweni zokulawula uketshezi. Le valve yakhiwe ibe nembobo noma imbobo phakathi nendawo, evumela uketshezi ukuba ludlule kuyo. Kuvame ukusetshenziswa ezinhlelweni lapho isivinini esikhulu kanye nokulawulwa kokuqondisa koketshezi kubalulekile. I-valve yejethi engenalutho ngokuvamile iqukethe umzimba one-inlet ne-outlet, kanye ne-orifice noma idiski elilawula ukugeleza koketshezi. Lapho i-valve isendaweni evaliwe, i-orifice ivimba ukugeleza koketshezi. Njengoba i-valve ivulwa ngokususa i-orifice kude nesihlalo, uketshezi lungadlula phakathi nendawo engenalutho bese luphuma nge-outlet.

Ama-jet valves angenalutho avame ukusetshenziswa edamini lamanzi, kanye nokukhiqizwa kwamandla. Ziwusizo ikakhulukazi ekulawuleni ukugeleza koketshezi olunengcindezi ephezulu noma isivinini esikhulu, lapho kudingeka khona ukulawula okunembile nokusebenza kahle. Idizayini nezinto ezisetshenziswa kuma-valve ejethi angenalutho zingahluka kuye ngohlelo oluthile kanye nohlobo loketshezi olulawulwayo. Izinto ezinjengokucindezela, izinga lokushisa, nokuhambisana kwamakhemikhali zidinga ukucatshangelwa lapho kukhethwa i-valve yejethi engenalutho yohlelo oluthile. Ukugcinwa nokuhlolwa okuvamile kubalulekile ukuze kuqinisekiswe ukusebenza kahle kwala ma-valve futhi kuvimbele noma yikuphi ukuvuza noma ukwehluleka.

Amavalvu ethu angenalutho afakazele ukusebenza kwawo okuphezulu ezitshalweni zikagesi ophehlwa ngamanzi nasemadamini okunisela. Baqinisekisa ukuphuma kwamanzi okulawulwayo nokuhambisana nemvelo ngaphandle noma emathangeni angaphansi kwamanzi. Amanzi abuye ahlanganiswe nomoya-mpilo ngesikhathi esifanayo. Ukwakhiwa kwensimbi yekhwalithi ephezulu yamavalvu e-jet angenalutho ahlanganiswe nokuvala okunwebekayo/kwensimbi kwenza ukuchithwa kwamandla ngaphandle kwe-cavitation.

-Izici Zokuklama-

◆Ekufakweni kwedamu, amavalvu okulawula afana nama-Hollow jet valves afakwa ngemva kwamavalvu ovemvane ohlangothini lokuphuma. Lawa ma-valve ahlala esebenza njengama-valve okulawula ukugeleza noma okulawula. Ama-valve ejethi aklanyelwe ukwenza ukuqondisa noma ukulawula.

◆ukusebenza ohlelweni lokuphakelwa kwamanzi ngaphandle kokudlidliza njengokuvulwa kwevalvu.

-Izinzuzo-

◆Ukulungiswa okunembile

◆Ayikho i-cavitation

◆Akukho ukudlidliza

◆Ukusebenza mathupha kudinga amandla amancane. Kungakhathalekile ukuthi isiphi isimo se-piston, amandla adingekayo ukuze i-piston ivuleke futhi ivalwe iyafana.

◆Ngenxa yokuphumela emoyeni asikho isizathu sokuxokozela futhi asikho isidingo sokufaka isando samanzi esivimba amanzi phansi komfula.

◆Ukunakekela okulula

● Umkhombe wokushayela:Okuqhutshwa ngesandla/Kusebenza ugesi

●I-Flange iphetha: EN1092-1 PN10/16,ASME B16.5

●Ukuhlola nokuhlola: EN12266,ISO5208D

●Imidiya Yoketshezi: Amanzi

●Isikhathi Esisebenzayo: ≤70℃

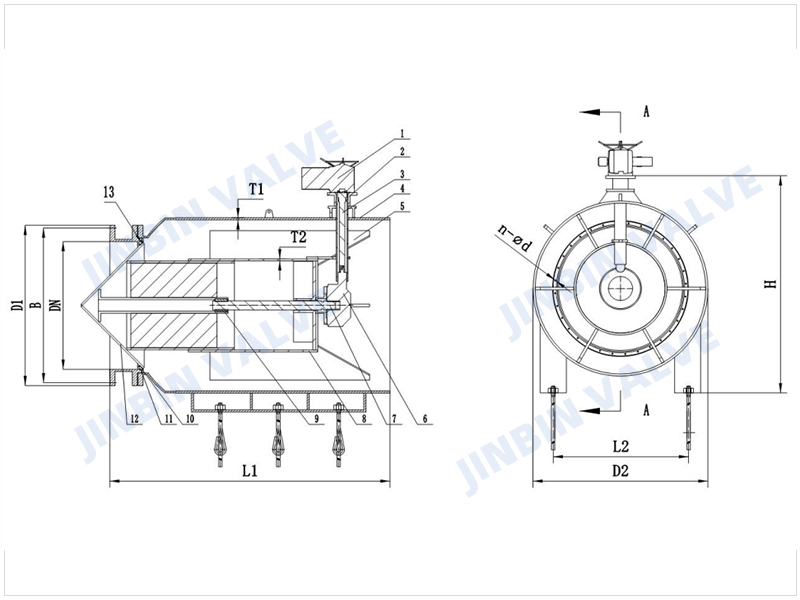

●Izingxenye Eziyinhloko Nezisetshenziswa

| No | Incazelo | Okubalulekile |

| 1 | I-actuator kagesi | Umhlangano |

| 2 | Ijoka | Insimbi ye-carbon |

| 3 | Umphini | I-ASTM SS420 |

| 4 | Umzimba | Insimbi ye-carbon |

| 5 | Ukuphoqa kabusha ubambo | Insimbi ye-carbon |

| 6 | I-Bevel gear | Umhlangano |

| 7 | Ukushayela shaft | I-SS420 |

| 8 | Umzimba we-shutter | Insimbi ye-carbon |

| 9 | Nut | I-Al.Bz noma i-Brass |

| 10 | Indandatho ebambayo | Insimbi ye-Carbon noma insimbi engagqwali |

| 11 | Indandatho ye-shutter seal | I-NBR/EPDM/SS304+Graphite |

| 12 | Ikhoni yokuvala | Insimbi ye-carbon |

| 13 | Indandatho yesihlalo somzimba | Insimbi engagqwali eshiselwe |

●Idatha ye-Dimensional

| I-DN(mm) | L1(mm) | I-D1(mm) | B(mm) | d | n | I-D2(mm) | L2(mm) | Wgt(kg) |

| 400 | 950 | 565 | 515 | M24 | 16 | 580 | 490 | 1460 |

| 600 | 1250 | 780 | 725 | M27 | 20 | 870 | 735 | 2320 |

| 800 | 1650 | 1015 | 950 | M30 | 24 | 1160 | 980 | 3330 |

| 1000 | 2050 | 1230 | 1160 | M33 | 28 | 1450 | 1225 | 4540 |

| 1200 | 2450 | 1455 | 1380 | M36 | 32 | 1740 | 1470 | 6000 |

| 1500 | 3050 | 1795 | 1705 | M45 | 40 | 2175 | 1840 | 8700 |

| 1800 | 3650 | 2115 | 2020 | M45 | 44 | 2610 | 2210 | 1230 |