100% Original 16 Inch Butterfly Valve - Motorised metal seated butterfly valve – Jinbin Valve

100% Original 16 Inch Butterfly Valve - Motorised metal seated butterfly valve – Jinbin Valve Detail:

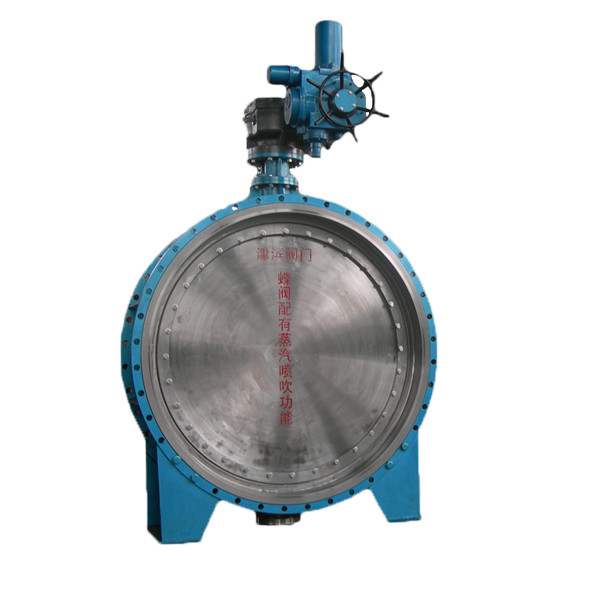

Electric double eccentric butterfly valve

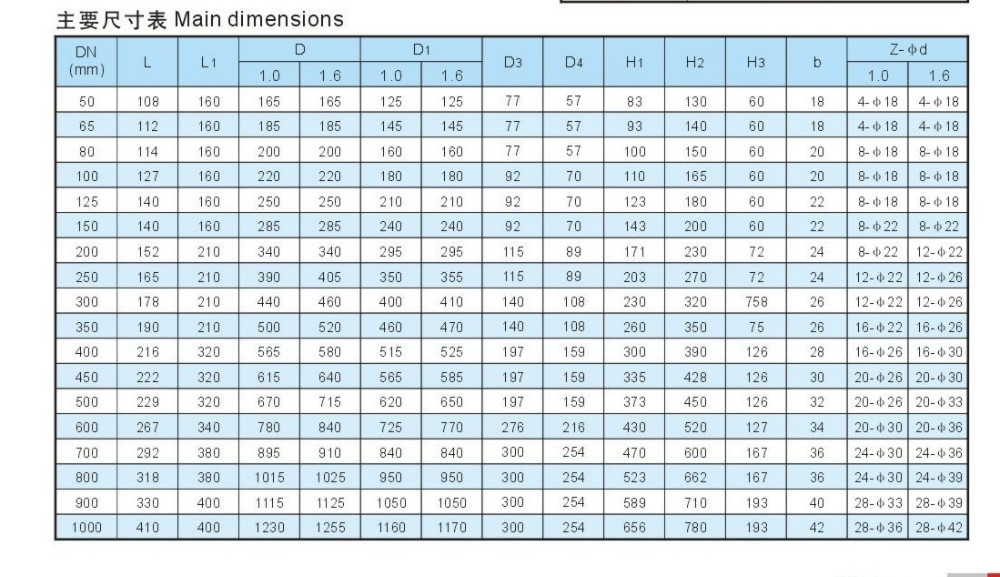

Size: 2”-80” / 40mm – 2000 mm

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, BS 5155, ISO 5752.

Flange Drilling: ANSI B 16.1, BS4504, DIN PN 10 / PN 16, JIS 5K, 10K, 16K.

Test: API 598.

|

Working Pressure |

PN10 / PN16 |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

|

Parts |

Materials |

|

Body |

Cast iron, ductile iron, carbon steel, stainless steel |

|

Disc |

Nickel ductile iron / Al bronze / Stainless steel |

|

Seat |

EPDM / NBR / VITON / PTFE |

|

Stem |

Stainless steel / Carbon steel |

|

Bushing |

PTFE |

|

“O” ring |

PTFE |

|

Worm gearbox |

Cast iron / Ductile iron |

The product is used for throttling or shutting off the flow of corrosive or non corrosive gased, liquids and semi liquid. It can be installed in any selected position in pipelines in the industries of petroleum processing, chemicals, food, medicine, textile, paper making, hydroelectricity engineering, building, water supply and sewage, metallurgy, energy engineering as well as light industry.

Product detail pictures:

Related Product Guide:

Camshafts, Valves, And Other Intermittent Mechanisms | Grooved Butterfly Valve

RHI Magnesita (LON:RHIM) Earns “Buy” Rating from Peel Hunt | Flange Spring No Return Check Valve

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for 100% Original 16 Inch Butterfly Valve - Motorised metal seated butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Haiti, Vietnam, Paraguay, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!