18 Years Factory Metal Seated Gate Valve - lever operated middle line flanged butterfly valve – Jinbin Valve

18 Years Factory Metal Seated Gate Valve - lever operated middle line flanged butterfly valve – Jinbin Valve Detail:

lever operated middle line flanged butterfly valve

Size: 2”-48” / 40mm – 1200 mm

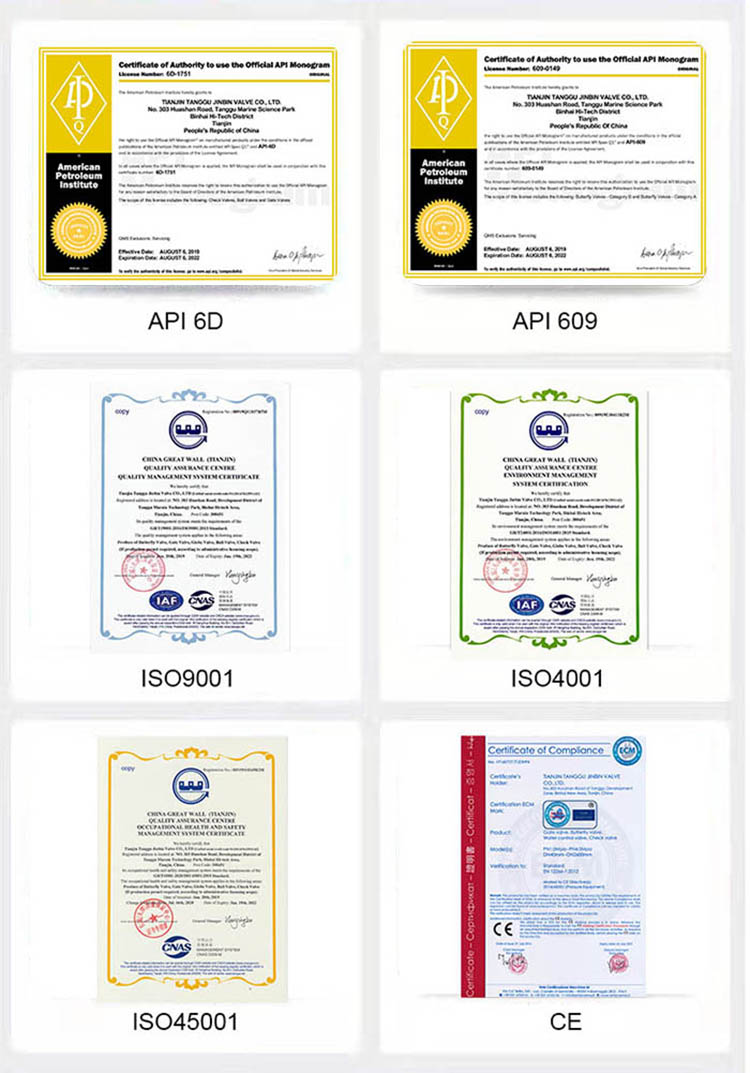

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, BS 5155, ISO 5752.

Flange Drilling: ANSI B 16.1, BS4504, DIN PN 10 / PN 16, JIS 5K, 10K, 16K.

Test: API 598.

|

Nominal Pressure |

PN10 PN16 |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

| Parts | Materials |

| Body | ductile iron, carbon steel, stainless steel |

| Disc | Nickel ductile iron / Al bronze / Stainless steel |

| Seat | EPDM / NBR / VITON / PTFE |

| Stem | Stainless steel |

The butterfly vavle is used for throttling or shutting off the flow of corrosive or non corrosive gased, liquids and semi liquid. It can be installed in any selected position in pipelines in the industries of petroleum processing, chemicals, food, medicine, textile, paper making, hydroelectricity engineering, building, water supply and sewage, metallurgy, energy engineering as well as light industry.

Tianjin Tanggu Jinbin Valve Co., Ltd. was founded in 2004, with registered capital of 113 million yuan, 156 employees, 28 sales agents of China,covering an area of 20,000 square meters in total, and 15,100 square meters for factories and offices.It is a valve manufacturer engaged in professional R&D, production and sales,a joint-stock enterprise integrating science, industry and trade

The company now has 3.5m vertical lathe, 2000mm * 4000mm boring and milling machine and other large processing equipment, multi-functional valve performance testing device and a series of perfect testing equipment

Product detail pictures:

Related Product Guide:

Global Control Valve Market Forecast to 2024 | Check Valve Dn100

DIARY-U.S. refinery operations-Phillips 66 Reports Process Unit Upset At Wood River, Ill. Refinery | | Flange Spring No Return Check Valve

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for 18 Years Factory Metal Seated Gate Valve - lever operated middle line flanged butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Norway, Amsterdam, Netherlands, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beauty and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!