2017 High quality Bsp Thread Ball Valve - Grooved fire protection butterfly valve – Jinbin Valve

2017 High quality Bsp Thread Ball Valve - Grooved fire protection butterfly valve – Jinbin Valve Detail:

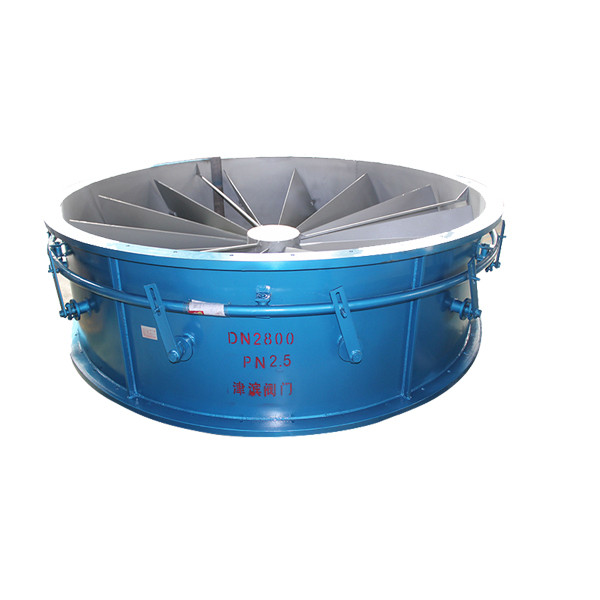

Grooved end fire protection butterfly valve

Size: 2”-12”/ 50mm –300 mm

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, DIN 3202 k1, ISO 5752, BS 5155, MSS SP-67.

Flange Drilling: ANSI B 16.1, BS4504, DIN PN 10 / PN 16.

Test: API 598.

Epoxy fusion coating.

Different lever operator.

|

Working Pressure |

10 bar / 16 bar |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

|

Parts |

Materials |

|

Body |

Cast iron / Ductile iron |

|

Disc |

Nickel ductile iron / Al bronze / Stainless steel |

|

Seat |

EPDM / NBR / VITON / PTFE |

|

Stem |

Stainless steel / Carbon steel |

|

Bushing |

PTFE |

|

“O” ring |

PTFE |

|

Pin |

Stainless steel |

|

Key |

Stainless steel |

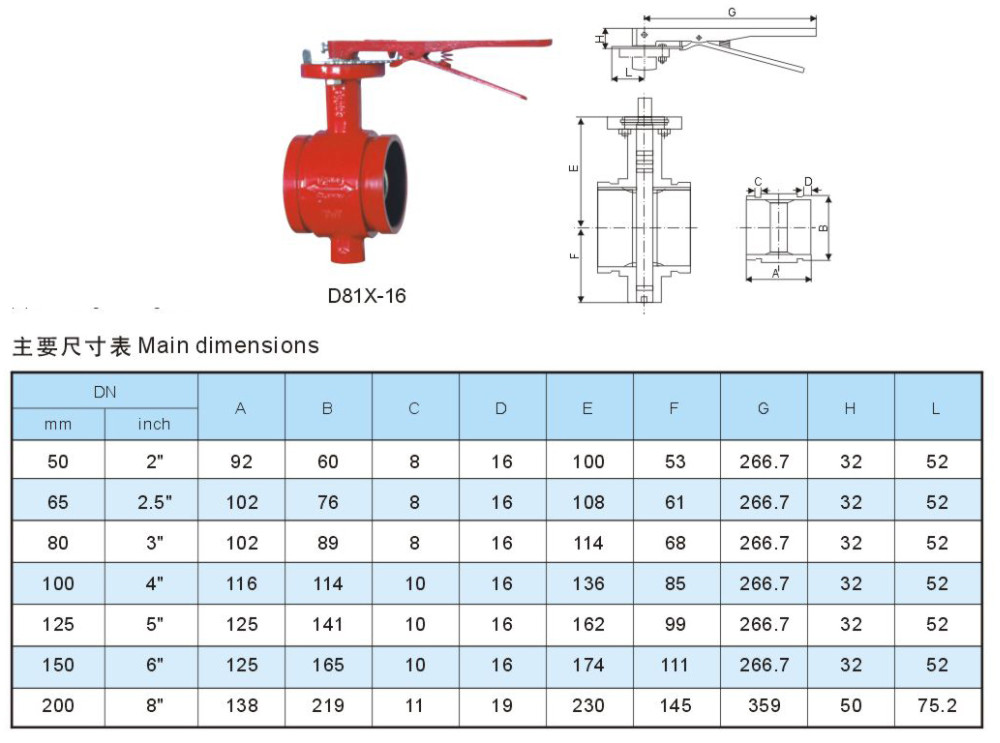

Technical data:

Structure and application:

Fire butterfly groove between the United States and Germany are the introduction of similar design and manufacture of advanced products and a series of new connection valves.It has installed express,simple,simple,safe,reliable,not subject to restrictions on the installation site,piping and valves to facilities maintenance,noise and vibration have a certain perspective of the scope has to overcome the pipelines to connect the different axis arising from poor imitation to solve the temperature difference have advantage.

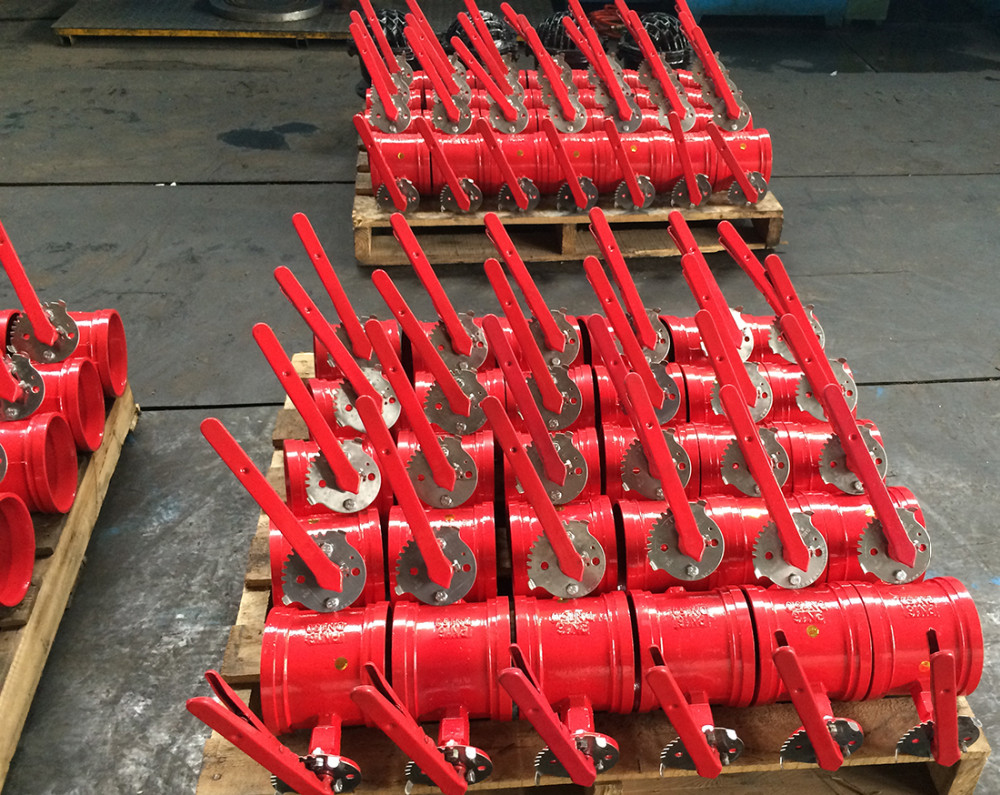

Product detail pictures:

Related Product Guide:

Radios: Build your own! | Flange Spring No Return Check Valve

Global Regulating Valve Market Analysis Report 2019-2024: Regulator, Adams Valve, HOKE, Casco, Jordan Valve, Red And White Valve, Eminem | Grooved Butterfly Valve

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for 2017 High quality Bsp Thread Ball Valve - Grooved fire protection butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Iraq, Algeria, Thailand, With excellent solutions, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We'll satisfy you with our qualified service!

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!