2017 wholesale priceRubber Flap Valve - Double offset Butterfly valve with rubber seat – Jinbin Valve

2017 wholesale priceRubber Flap Valve - Double offset Butterfly valve with rubber seat – Jinbin Valve Detail:

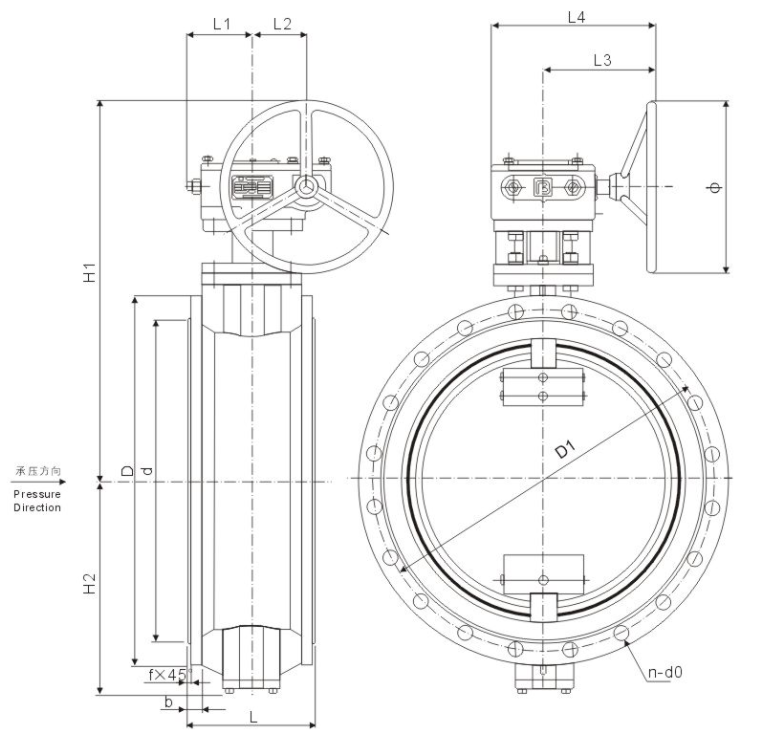

Resilient seat double Eccentric Flange Butterfly valve

Size: DN 100 – DN2800

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, ISO 5752, BS EN 558, BS 5155.

Flange Drilling: ANSI B 16.1, BS EN 1092, DIN 2501 PN 10/16, BS 10 Table E.

Test: API 598.

|

Working Pressure |

PN10 / PN16 |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

Shell and seal tests for each valve is done and recorded before package to make sure the product quality. The test media is water in room conditions.

|

Parts |

Materials |

|

Body |

Ductile iron, carbon steel, stainless steel |

|

Disc |

Nickel ductile iron / Al bronze / Stainless steel |

|

Seat |

EPDM / NBR / VITON / PTFE |

|

Stem |

Stainless steel / Carbon steel |

|

Bushing |

PTFE |

|

“O” ring |

PTFE |

If need the drawing details, please feel free to contact.

The product is used for throttling or shutting off the flow of corrosive or non corrosive gased, liquids and semi liquid. It can be installed in any selected position in pipelines in the industries of petroleum processing, chemicals, food, medicine, textile, paper making, hydroelectricity engineering, building, water supply and sewage, metallurgy, energy engineering as well as light industry.

Product detail pictures:

Related Product Guide:

Bike Check: Joshua Barth’s Solid Strike – European DH Cup 2018 | Flange Spring No Return Check Valve

Fire protection pumps: Updates to NFPA 20 – Consulting | Rising Stem Type Gate Valve

The company upholds the philosophy of "Be No.1 in quality, be rooted on credit and trustworthiness for growth", will continue to serve old and new customers from home and overseas whole-heatedly for 2017 wholesale priceRubber Flap Valve - Double offset Butterfly valve with rubber seat – Jinbin Valve , The product will supply to all over the world, such as: Frankfurt, San Francisco, Slovenia, Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!