Cheapest Factory Carbon Steel Flanged Ball Valve - Cast iron flange globe valve – Jinbin Valve

Cheapest Factory Carbon Steel Flanged Ball Valve - Cast iron flange globe valve – Jinbin Valve Detail:

Carbon iron flange globe valve

Cast iron flange globe valves are made of movable plug as disc with flat or conical surface sealing to seal. Normally,the plug is connected to a stem which is operated by screw action as a straight line using a hand wheels. Normally, this kind of globe valves just used for full open and full close, do not for flow regulation. The pressure is from PN16 to PN160 and working temperature is from -29 to 450 degree.This cast iron globe valves are widely used for petroleum, chemical, pharmacy, chemical andpowder industries pipelines to throttle the media. There are manual, bevel gear, electric and pneumatic actuated actuators.

Size: DN50-DN300

Pressure: PN16, PN25, PN40

|

Nominal pressure |

1.6 |

2.5 |

4.0 |

6.4 |

|

Shell test |

2.4 |

3.8 |

6.0 |

9.6 |

|

Water seal test |

1.8 |

2.8 |

4.4 |

7.4 |

|

Upper seal |

1.8 |

2.8 |

4.4 |

7.4 |

|

Air seal |

0.4-0.7 |

|||

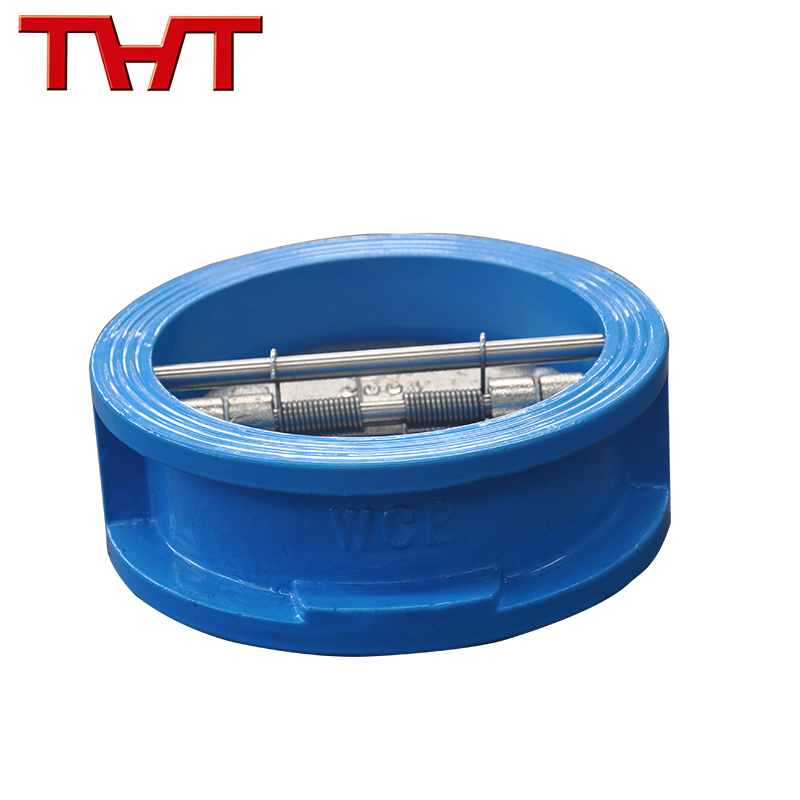

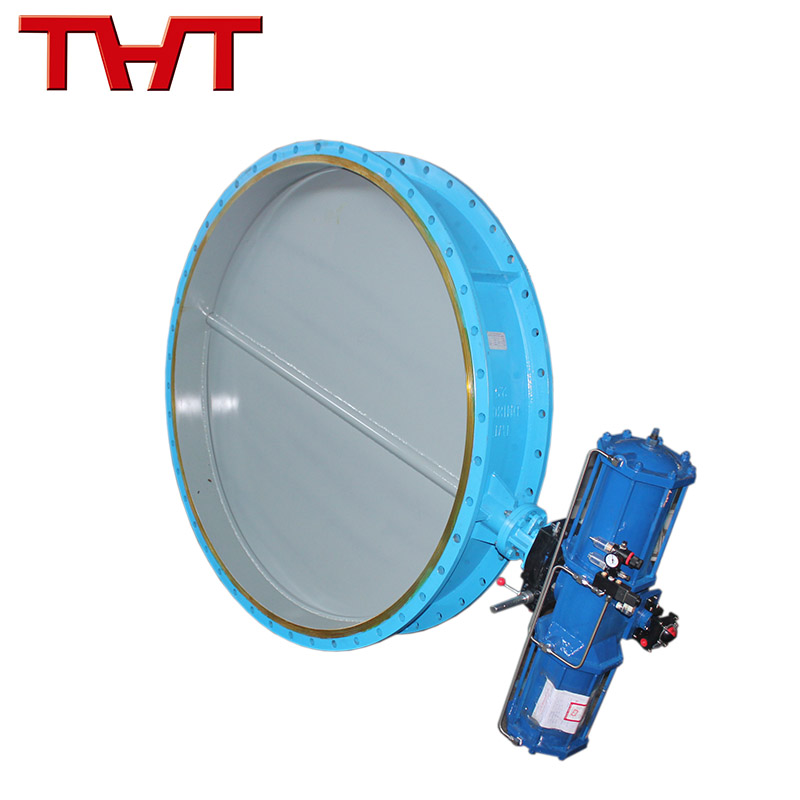

Product detail pictures:

Related Product Guide:

Specialized Epic 2018: Farewell FSR Hello Single Pivot | Check Valve Dn100

Global Control Valve Market Forecast to 2024 | Check Valve Dn100

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm to the long-term to develop together with consumers for mutual reciprocity and mutual advantage for Cheapest Factory Carbon Steel Flanged Ball Valve - Cast iron flange globe valve – Jinbin Valve , The product will supply to all over the world, such as: Holland, UK, Adelaide, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.