China Factory for Large Diameter Gate Valves Water - Turbo desulphurization Butterfly valve – Jinbin Valve

China Factory for Large Diameter Gate Valves Water - Turbo desulphurization Butterfly valve – Jinbin Valve Detail:

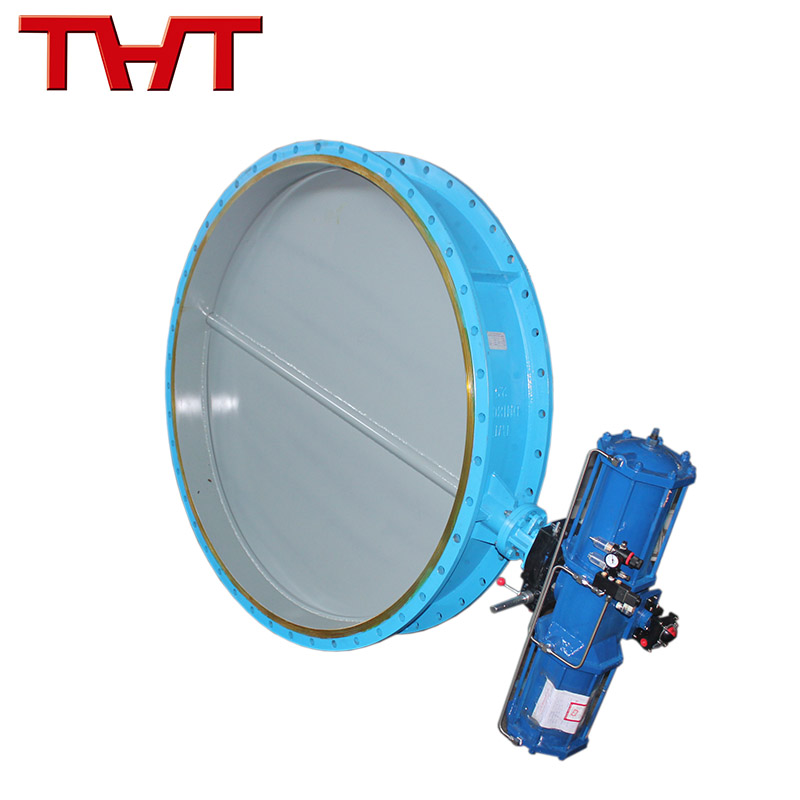

Turbo desulphurization Butterfly valve

The desulfurization butterfly valve fully considers the corrosion and wear of the desulfurization slurry on the valve, ensuring that the valve plate lining is a component that can contact the slurry, while other components are not corroded by the limestone (or lime paste) slurry. Therefore, the valve body and the valve stem do not need to use expensive alloy (2205) material, which greatly saves costs. The unique seat design of the desulfurization butterfly valve completely separates the valve body from the fluid medium. Compared with other similar valves, it has a better valve seat firming method, quick replacement of the valve seat, zero leakage of the valve, and low friction. The butterfly valve disc is made of high-performance alloy (2205) material to effectively resist the corrosion and wear of the slurry.

|

Working Pressure |

10 bar / 16 bar |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

|

Parts |

Materials |

|

Body |

Cast iron, ductile iron, carbon steel |

|

Disc |

Nickel ductile iron / Al bronze / Stainless steel |

|

Seat |

EPDM / NBR / VITON / PTFE |

|

Stem |

Stainless steel / Carbon steel |

|

Bushing |

PTFE |

|

“O” ring |

PTFE |

|

Worm gearbox |

Cast iron / Ductile iron |

The desulfurization butterfly valve can be widely used for regulating and intercepting fluid lines such as hydropower, sewage, construction, air conditioning, petroleum, chemical, food, medicine, textile, papermaking, water supply and drainage, etc.

Product detail pictures:

Related Product Guide:

Demand for Cryogenic Valve Increasing due to Growing Offshore and Inland Transportation of Gases | Check Valve Dn100

Physics can explain human innovation and enlightenment — Quartz | Flange Spring No Return Check Valve

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for China Factory for Large Diameter Gate Valves Water - Turbo desulphurization Butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: South Africa, Naples, India, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! You should contact us right away!

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.