factory customized Pneumatic Knife Valve - Manual resilient seat flanged butterfly valve – Jinbin Valve

factory customized Pneumatic Knife Valve - Manual resilient seat flanged butterfly valve – Jinbin Valve Detail:

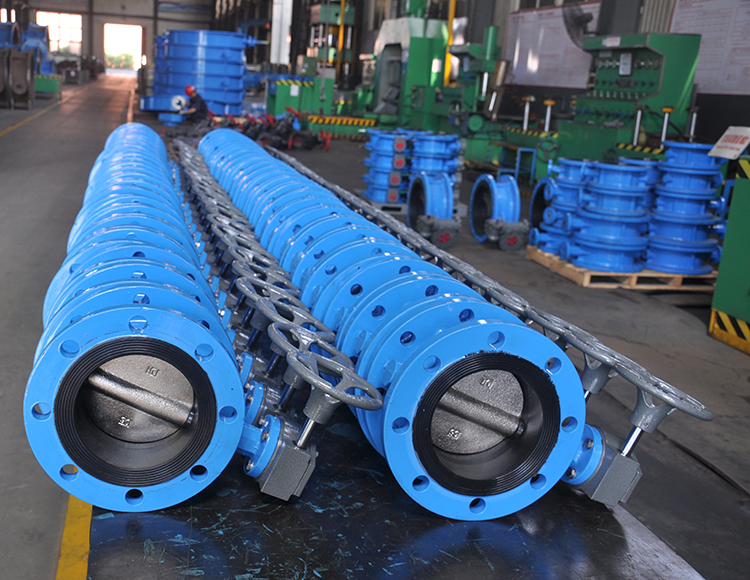

Manual resilient seat flanged butterfly valve

Size: 2”-48” / 40mm – 1200 mm

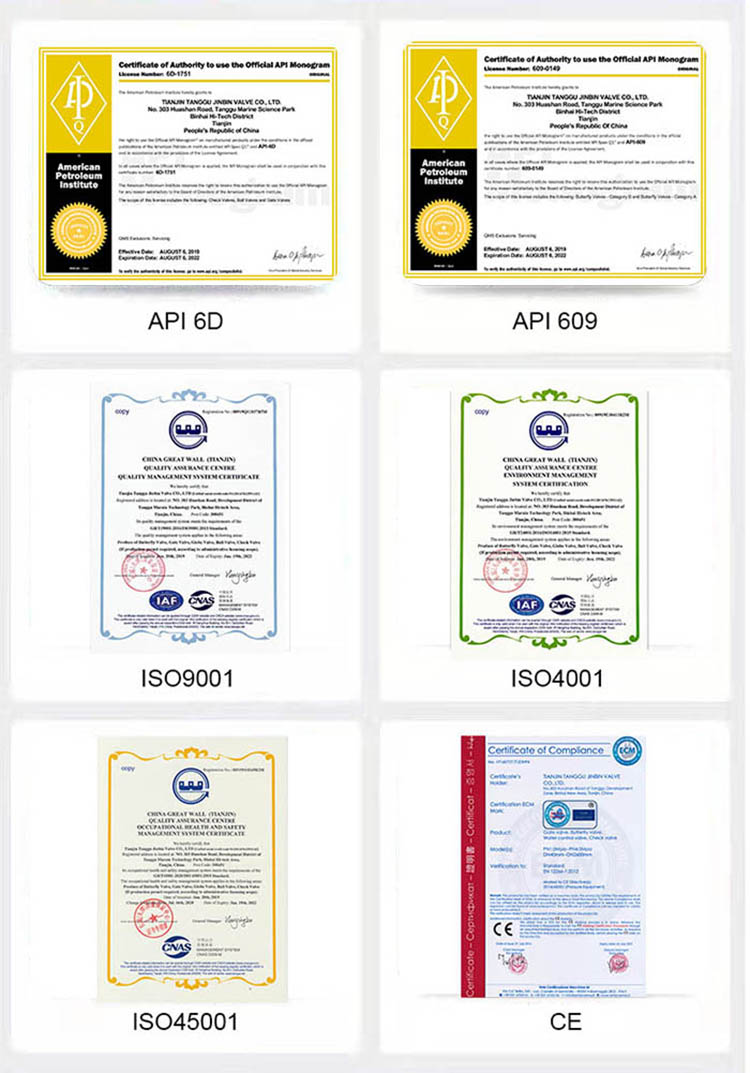

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, BS 5155, ISO 5752.

Flange Drilling: ANSI B 16.1, BS4504, DIN PN 10 / PN 16, JIS 5K, 10K, 16K.

Test: API 598.

|

Nominal Pressure |

PN10 PN16 |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

| Parts | Materials |

| Body | ductile iron, carbon steel, stainless steel |

| Disc | Nickel ductile iron / Al bronze / Stainless steel |

| Seat | EPDM / NBR / VITON / PTFE |

| Stem | Stainless steel |

The butterfly valve is used for throttling or shutting off the flow of corrosive or non corrosive gased, liquids and semi liquid. It can be installed in any selected position in pipelines in the industries of petroleum processing, chemicals, food, medicine, textile, paper making, hydroelectricity engineering, building, water supply and sewage, metallurgy, energy engineering as well as light industry.

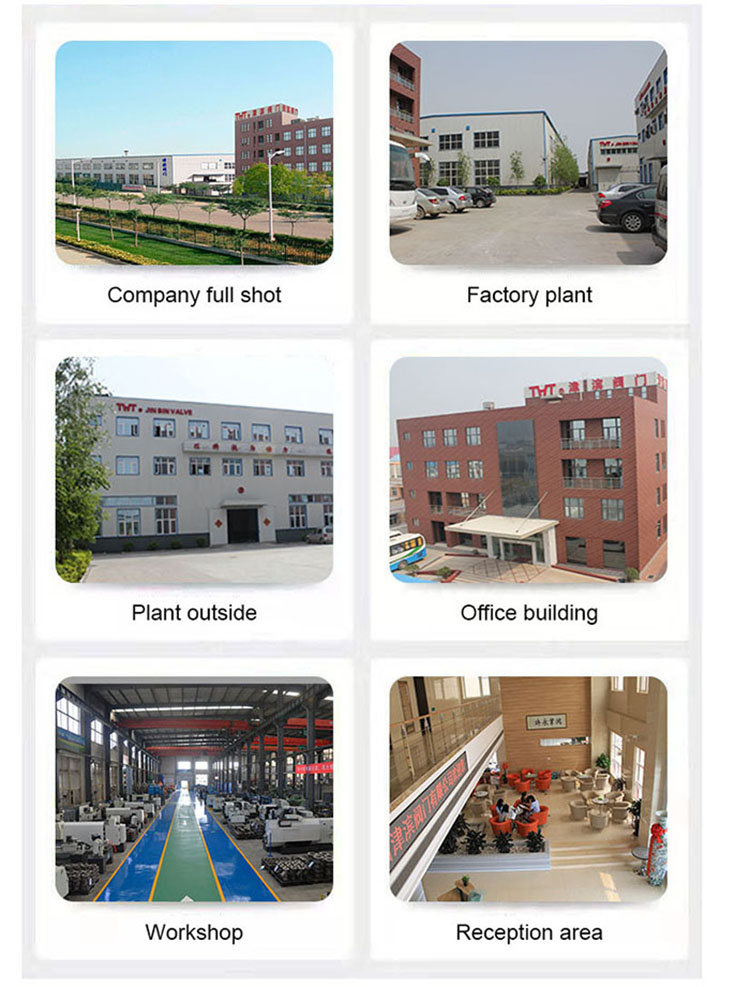

Tianjin Tanggu Jinbin Valve Co., Ltd. was founded in 2004, with registered capital of 113 million yuan, 156 employees, 28 sales agents of China,covering an area of 20,000 square meters in total, and 15,100 square meters for factories and offices.It is a valve manufacturer engaged in professional R&D, production and sales,a joint-stock enterprise integrating science, industry and trade.

The company now has 3.5m vertical lathe, 2000mm * 4000mm boring and milling machine and other large processing equipment, multi-functional valve performance testing device and a series of perfect testing equipment

Product detail pictures:

Related Product Guide:

The Shed Opens in NYC Today – Architects’ Guide to Glass & Metal | Grooved Butterfly Valve

Antivaccine cardiologist Jack Wolfson and the resurrection of false balance about vaccines…again! | Flange Spring No Return Check Valve

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for factory customized Pneumatic Knife Valve - Manual resilient seat flanged butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Croatia, Hungary, Brasilia, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality items we offer, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We are confident that we'll share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!