Factory selling Cast Steel Knife Gate Valve - Manual resilient seat flanged butterfly valve – Jinbin Valve

Factory selling Cast Steel Knife Gate Valve - Manual resilient seat flanged butterfly valve – Jinbin Valve Detail:

Manual resilient seat flanged butterfly valve

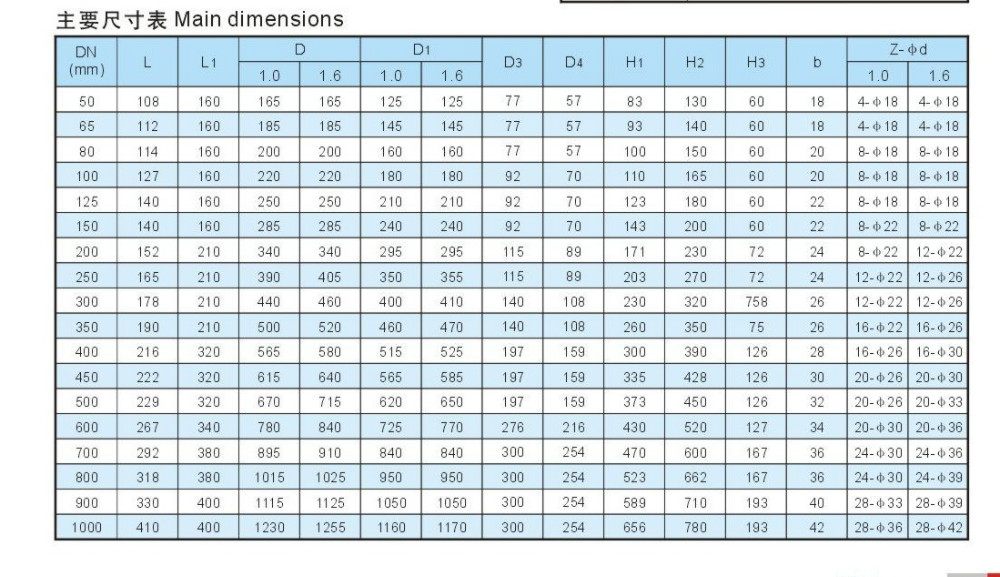

Size: 2”-48” / 40mm – 1200 mm

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, BS 5155, ISO 5752.

Flange Drilling: ANSI B 16.1, BS4504, DIN PN 10 / PN 16, JIS 5K, 10K, 16K.

Test: API 598.

|

Working Pressure |

PN10 / PN16 |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

|

Parts |

Materials |

|

Body |

Cast iron, ductile iron, carbon steel, stainless steel |

|

Disc |

Nickel ductile iron / Al bronze / Stainless steel |

|

Seat |

EPDM / NBR / VITON / PTFE |

|

Stem |

Stainless steel / Carbon steel |

|

Bushing |

PTFE |

|

“O” ring |

PTFE |

|

Worm gearbox |

Cast iron / Ductile iron |

The product is used for throttling or shutting off the flow of corrosive or non corrosive gased, liquids and semi liquid. It can be installed in any selected position in pipelines in the industries of petroleum processing, chemicals, food, medicine, textile, paper making, hydroelectricity engineering, building, water supply and sewage, metallurgy, energy engineering as well as light industry.

Product detail pictures:

Related Product Guide:

City of Newport Responds to Pair of Flooding Events | Grooved Butterfly Valve

RHI Magnesita (LON:RHIM) Stock Rating Reaffirmed by Peel Hunt | Flange Spring No Return Check Valve

The corporation upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will proceed to provide aged and new buyers from home and abroad whole-heatedly for Factory selling Cast Steel Knife Gate Valve - Manual resilient seat flanged butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Nigeria, Plymouth, belarus, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.