Factory Supply Rubber Disc Check Valve - microresistance slow closing flange check Valve with counterweight – Jinbin Valve

Factory Supply Rubber Disc Check Valve - microresistance slow closing flange check Valve with counterweight – Jinbin Valve Detail:

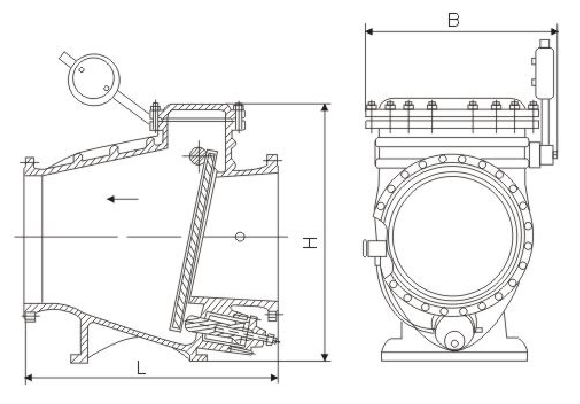

Flange Check Valve with counterweight

For BS 4504 BS EN1092-2 PN10 / PN16/ PN25 flange mounting.

Face-to-Face dimension conforms to ISO 5752 / BS EN558.

Epoxy fusion coating.

|

Working Pressure |

PN10 / PN16 / PN25 |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, sewage etc. |

Shell and seal tests for each valve is done and recorded before package to make sure the product quality. The test media is water in room conditions.

|

Part |

Material |

|

Body |

Ductile Iron/Carbon steel |

|

Disc |

Ductile Iron / Stainless Steel |

|

Spring |

Stainless Steel |

|

Shaft |

Stainless Steel |

|

Seat Ring |

NBR / EPDM |

|

Cylinder/Piston |

Stainless steel |

If need the drawing details, please feel free to contact.

This check valve is used for preventing the back-going of medium in pipelines and equipments, and the pressure of medium will bring the result of opening and closing automatically.When the medium is back-going, valve disc will automaticaly closed to avoid accidents.

Product detail pictures:

Related Product Guide:

Industrial Valve Market Key Findings, Major Companies, Global Industry Size, Segmentation, Share, Regional Outlook, Competitive Strategies and Forecasts 2019 To 2023 – Press Release | Flange Spring No Return Check Valve

The 10 Best Commuter Bikes At Any Budget of 2018 • Gear Patrol | Check Valve Dn100

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for Factory Supply Rubber Disc Check Valve - microresistance slow closing flange check Valve with counterweight – Jinbin Valve , The product will supply to all over the world, such as: Finland, French, Lisbon, We seriously promise that we provide all the customers with the best quality products, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.