Good Wholesale VendorsGate-Valve - Turbo desulphurization Butterfly valve – Jinbin Valve

Good Wholesale VendorsGate-Valve - Turbo desulphurization Butterfly valve – Jinbin Valve Detail:

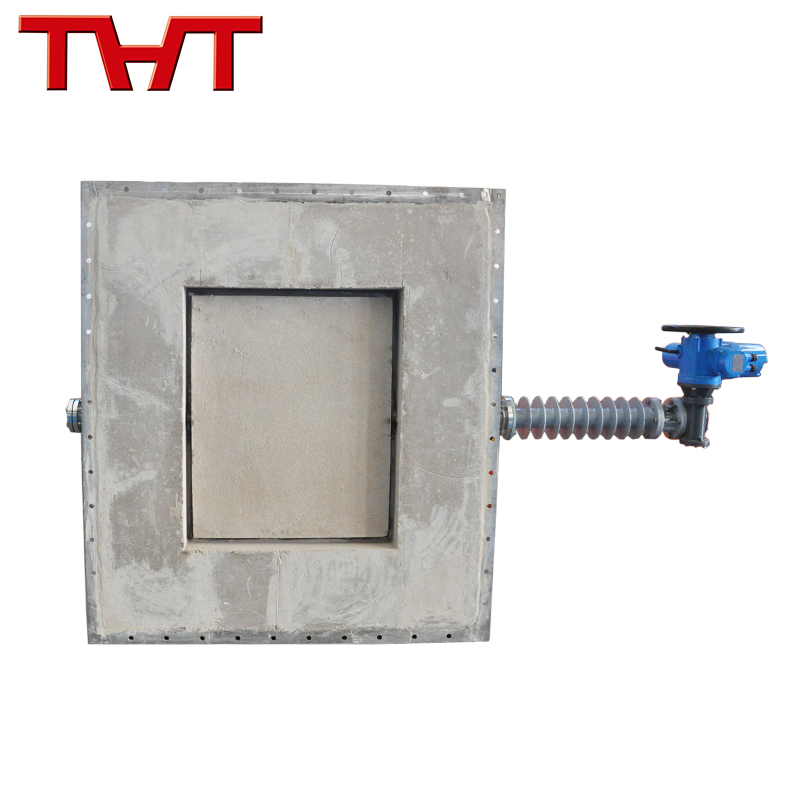

Turbo desulphurization Butterfly valve

The desulfurization butterfly valve fully considers the corrosion and wear of the desulfurization slurry on the valve, ensuring that the valve plate lining is a component that can contact the slurry, while other components are not corroded by the limestone (or lime paste) slurry. Therefore, the valve body and the valve stem do not need to use expensive alloy (2205) material, which greatly saves costs. The unique seat design of the desulfurization butterfly valve completely separates the valve body from the fluid medium. Compared with other similar valves, it has a better valve seat firming method, quick replacement of the valve seat, zero leakage of the valve, and low friction. The butterfly valve disc is made of high-performance alloy (2205) material to effectively resist the corrosion and wear of the slurry.

|

Working Pressure |

10 bar / 16 bar |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

|

Parts |

Materials |

|

Body |

Cast iron, ductile iron, carbon steel |

|

Disc |

Nickel ductile iron / Al bronze / Stainless steel |

|

Seat |

EPDM / NBR / VITON / PTFE |

|

Stem |

Stainless steel / Carbon steel |

|

Bushing |

PTFE |

|

“O” ring |

PTFE |

|

Worm gearbox |

Cast iron / Ductile iron |

The desulfurization butterfly valve can be widely used for regulating and intercepting fluid lines such as hydropower, sewage, construction, air conditioning, petroleum, chemical, food, medicine, textile, papermaking, water supply and drainage, etc.

Product detail pictures:

Related Product Guide:

Deep Breathing with YearOne and Accurate Exhaust Products for Mopars | Check Valve Dn100

Demand for Cryogenic Valve Increasing due to Growing Offshore and Inland Transportation of Gases | Check Valve Dn100

Just about every member from our large efficiency income crew values customers' wants and enterprise communication for Good Wholesale VendorsGate-Valve - Turbo desulphurization Butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Brasilia, Czech Republic, Botswana, Our expert engineering team will generally be prepared to serve you for consultation and feedback. We're able to also give you with free of charge samples to meet your requirements. Best efforts will likely be produced to provide you the best service and merchandise. When you are keen on our business and items, make sure you speak to us by sending us emails or call us quickly. In an effort to know our merchandise and company extra, you may come to our factory to view it. We'll generally welcome guests from all over the world to our business to create business relations with us. Be sure to feel cost-free to speak to us for small business and we believe we are going to share the best trading experience with all our merchants.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!