High PerformanceWelding Ball Valve - Manual resilient seat flanged butterfly valve – Jinbin Valve

High PerformanceWelding Ball Valve - Manual resilient seat flanged butterfly valve – Jinbin Valve Detail:

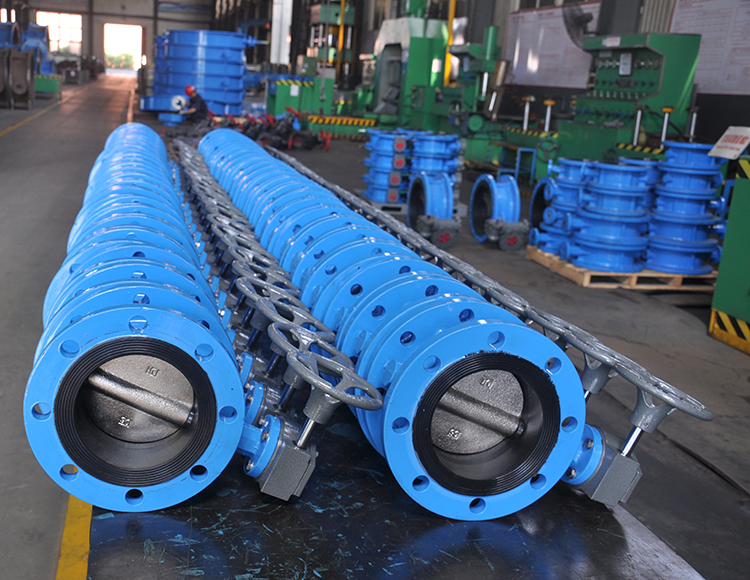

Manual resilient seat flanged butterfly valve

Size: 2”-48” / 40mm – 1200 mm

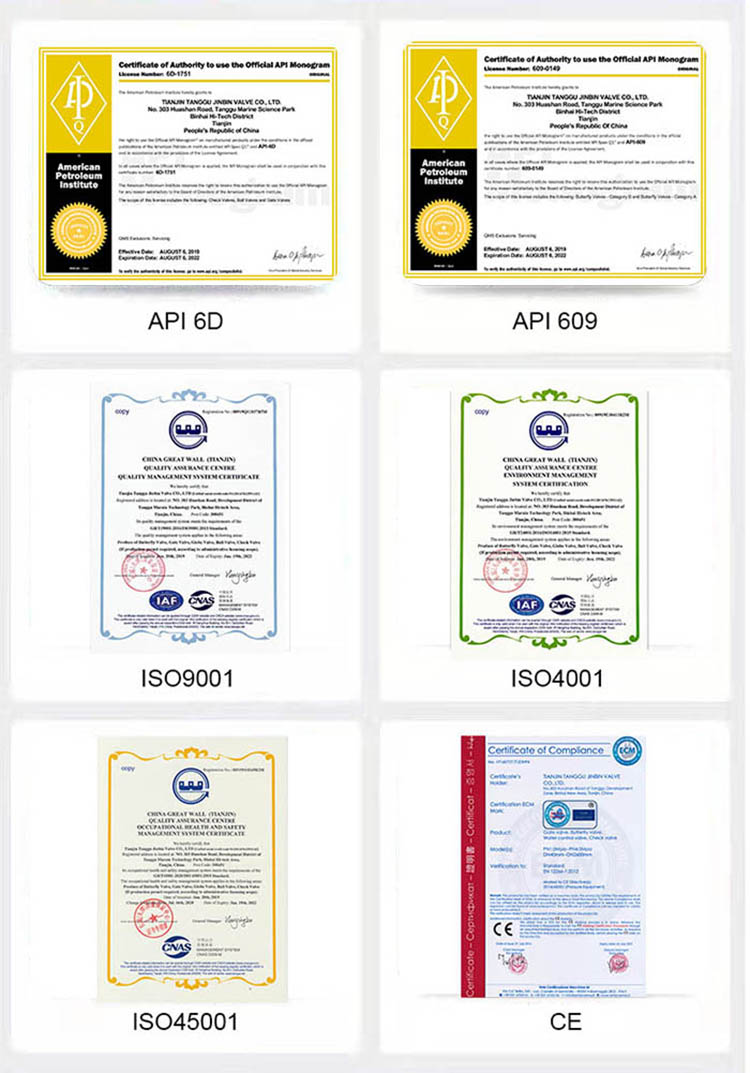

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, BS 5155, ISO 5752.

Flange Drilling: ANSI B 16.1, BS4504, DIN PN 10 / PN 16, JIS 5K, 10K, 16K.

Test: API 598.

|

Nominal Pressure |

PN10 PN16 |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

| Parts | Materials |

| Body | ductile iron, carbon steel, stainless steel |

| Disc | Nickel ductile iron / Al bronze / Stainless steel |

| Seat | EPDM / NBR / VITON / PTFE |

| Stem | Stainless steel |

The butterfly valve is used for throttling or shutting off the flow of corrosive or non corrosive gased, liquids and semi liquid. It can be installed in any selected position in pipelines in the industries of petroleum processing, chemicals, food, medicine, textile, paper making, hydroelectricity engineering, building, water supply and sewage, metallurgy, energy engineering as well as light industry.

Tianjin Tanggu Jinbin Valve Co., Ltd. was founded in 2004, with registered capital of 113 million yuan, 156 employees, 28 sales agents of China,covering an area of 20,000 square meters in total, and 15,100 square meters for factories and offices.It is a valve manufacturer engaged in professional R&D, production and sales,a joint-stock enterprise integrating science, industry and trade.

The company now has 3.5m vertical lathe, 2000mm * 4000mm boring and milling machine and other large processing equipment, multi-functional valve performance testing device and a series of perfect testing equipment

Product detail pictures:

Related Product Guide:

Ram Multifunction Tailgate vs Ford, GMC, and Honda | Rising Stem Type Gate Valve

Bühler Tubex scale utilizes electromagnetic valves to lower energy usage | World-grain.com | Check Valve Dn100

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for High PerformanceWelding Ball Valve - Manual resilient seat flanged butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Sevilla, Oslo, Ukraine, We have been fully aware of our customer's needs. We deliver high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.