High reputation Check Valve - Wafer type ductile iron center line butterfly valve – Jinbin Valve

High reputation Check Valve - Wafer type ductile iron center line butterfly valve – Jinbin Valve Detail:

Wafer type ductile iron center line butterfly valve

Size: 2”-12”/ 50mm –300 mm

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, DIN 3202 k1, ISO 5752, BS 5155, MSS SP-67.

Flange Drilling: ANSI B 16.1, BS4504, DIN PN 10 / PN 16.

Test: API 598.

Epoxy fusion coating.

Different lever operator.

|

Working Pressure |

10 bar / 16 bar |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

|

Parts |

Materials |

|

Body |

Cast iron / Ductile iron |

|

Disc |

Nickel ductile iron / Al bronze / Stainless steel |

|

Seat |

EPDM / NBR / VITON / PTFE |

|

Stem |

Stainless steel / Carbon steel |

|

Bushing |

PTFE |

|

“O” ring |

PTFE |

|

Pin |

Stainless steel |

|

Key |

Stainless steel |

Technical data:

The product is used for throttling or shutting off the flow of corrosive or non corrosive gases, liquids and semiliquid. It can be installed in any selected position in pipelines in the industries of petroleum processing, chemicals, food, medicine, textile, paper making, hydroelectricity engineering, building, water supply and sewage, metallurgy, energy engineering as well as light industry.

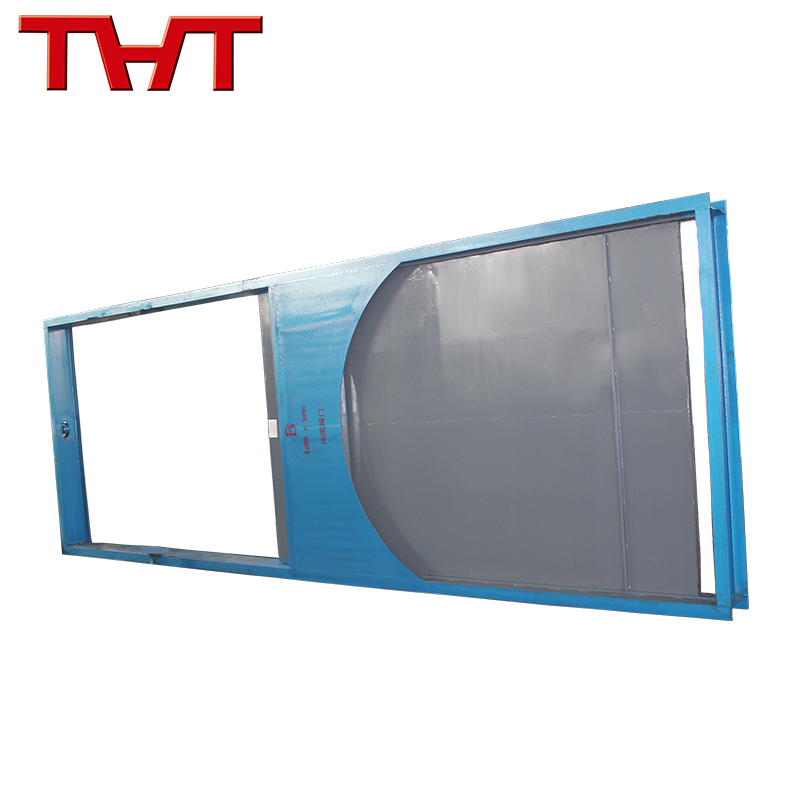

Product detail pictures:

Related Product Guide:

Radios: Build your own! | Grooved Butterfly Valve

RP embraces adventure with expanding, gear-hauling Rebel camper van | Flange Spring No Return Check Valve

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for High reputation Check Valve - Wafer type ductile iron center line butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Ukraine, Madras, South Africa, Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.