Manufacturer for Check Valve 10 Inch - Electric actuator resilent wafer butterfly valve – Jinbin Valve

Manufacturer for Check Valve 10 Inch - Electric actuator resilent wafer butterfly valve – Jinbin Valve Detail:

Electric Operated Wafer Butterfly Valve

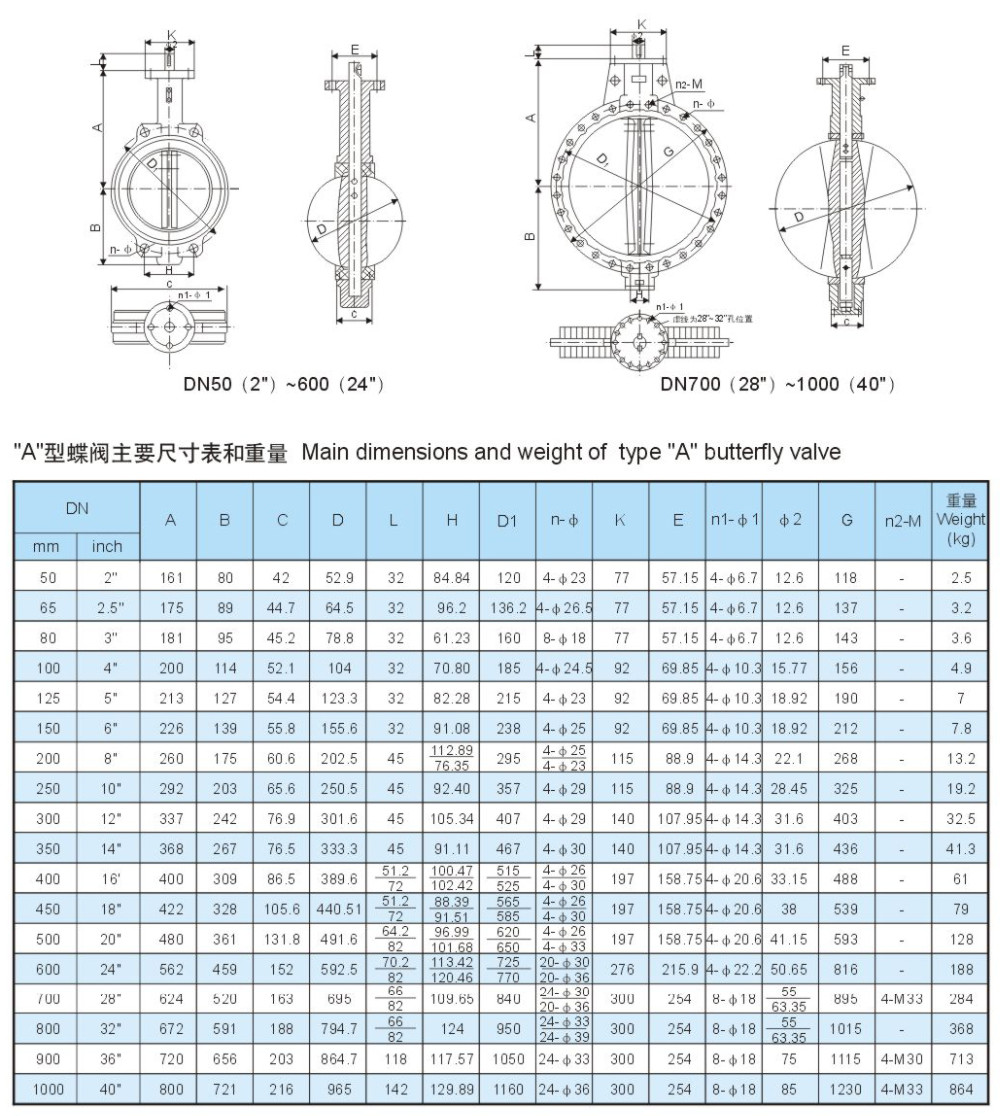

Size: 2”-24” / 50mm – 600 mm

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, ISO 5752, BS EN 558, BS 5155, MS SP-67.

Flange Drilling: ANSI B 16.1, BS EN 1092, DIN 2501 PN 10/16, BS 10 Table E, JIS B2212/2213 5K, 10K, 16K.

Test: API 598.

|

Working Pressure |

PN10 / PN16 |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

|

Parts |

Materials |

|

Body |

Cast iron, ductile iron, carbon steel, stainless steel |

|

Disc |

Nickel ductile iron / Al bronze / Stainless steel |

|

Seat |

EPDM / NBR / VITON / PTFE |

|

Stem |

Stainless steel / Carbon steel |

|

Bushing |

PTFE |

|

“O” ring |

PTFE |

Technical data:

The product is used for throttling or shutting off the flow of corrosive or non corrosive gased, liquids and semi liquid. It can be installed in any selected position in pipelines in the industries of petroleum processing, chemicals, food, medicine, textile, paper making, hydroelectricity engineering, building, water supply and sewage, metallurgy, energy engineering as well as light industry.

Product detail pictures:

Related Product Guide:

No Power At Wot, Revs Fine In Neutral | Rising Stem Type Gate Valve

The Global Market for Zirconium (2019-2024): Anticipating a CAGR of 6.25% | Slide Gate Valve

"Quality first, Honesty as base, Sincere service and mutual profit" is our idea, in order to develop continuously and pursue the excellence for Manufacturer for Check Valve 10 Inch - Electric actuator resilent wafer butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Jordan, Amman, Yemen, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!