Manufacturer for Check Valve 10 Inch - Manual resilient seat flanged butterfly valve – Jinbin Valve

Manufacturer for Check Valve 10 Inch - Manual resilient seat flanged butterfly valve – Jinbin Valve Detail:

Manual resilient seat flanged butterfly valve

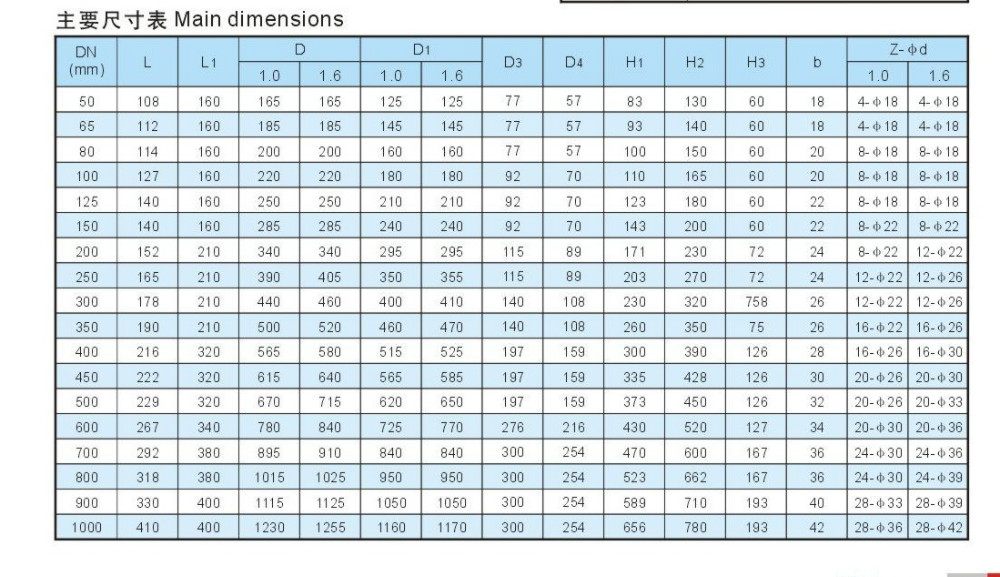

Size: 2”-48” / 40mm – 1200 mm

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, BS 5155, ISO 5752.

Flange Drilling: ANSI B 16.1, BS4504, DIN PN 10 / PN 16, JIS 5K, 10K, 16K.

Test: API 598.

|

Working Pressure |

PN10 / PN16 |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

|

Parts |

Materials |

|

Body |

Cast iron, ductile iron, carbon steel, stainless steel |

|

Disc |

Nickel ductile iron / Al bronze / Stainless steel |

|

Seat |

EPDM / NBR / VITON / PTFE |

|

Stem |

Stainless steel / Carbon steel |

|

Bushing |

PTFE |

|

“O” ring |

PTFE |

|

Worm gearbox |

Cast iron / Ductile iron |

The product is used for throttling or shutting off the flow of corrosive or non corrosive gased, liquids and semi liquid. It can be installed in any selected position in pipelines in the industries of petroleum processing, chemicals, food, medicine, textile, paper making, hydroelectricity engineering, building, water supply and sewage, metallurgy, energy engineering as well as light industry.

Product detail pictures:

Related Product Guide:

Next Sonoma County insurance risk: insurers dropping homeowner policies | Rising Stem Type Gate Valve

Radios: Build your own! | Grooved Butterfly Valve

Innovation, quality and reliability are the core values of our company. These principles today more than ever form the basis of our success as an internationally active mid-size company for Manufacturer for Check Valve 10 Inch - Manual resilient seat flanged butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Zimbabwe, Canberra, Mauritius, We offer the great variety of products in this field. Besides, customized orders are also available. What's more, you will enjoy our excellent services. In one word, your satisfaction is guaranteed. Welcome to visit our company! For more information, please come to our website.If any further inquiries, please feel free to contact us.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.