OEM/ODM China Gas Butterfly Valve - Motorised metal seated butterfly valve – Jinbin Valve

OEM/ODM China Gas Butterfly Valve - Motorised metal seated butterfly valve – Jinbin Valve Detail:

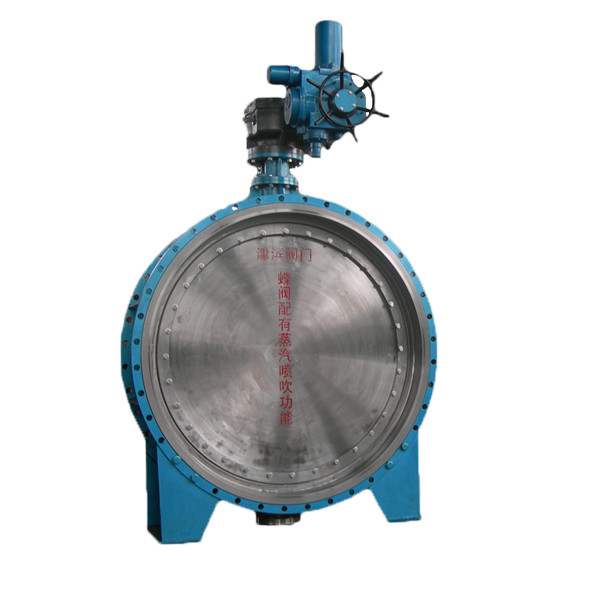

Electric double eccentric butterfly valve

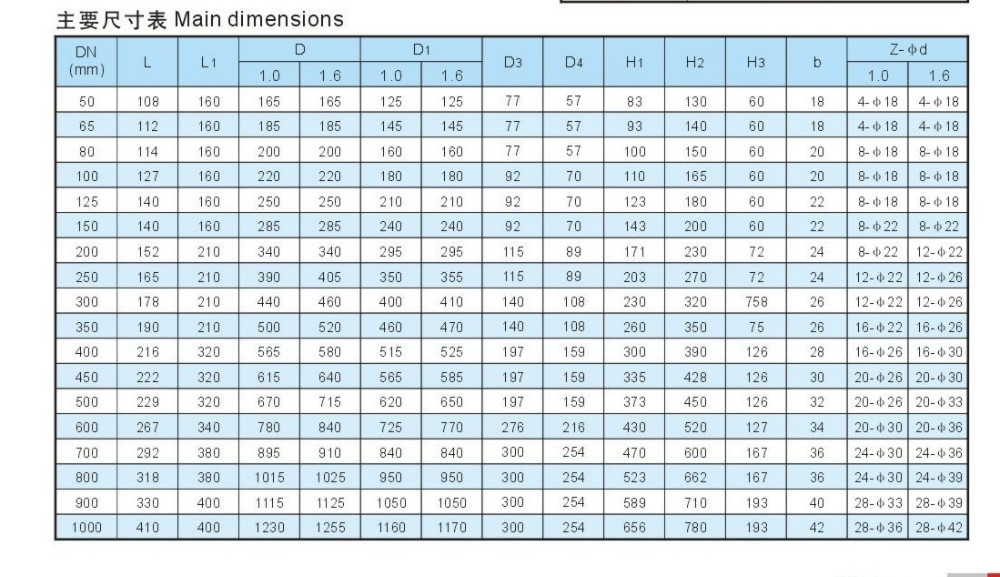

Size: 2”-80” / 40mm – 2000 mm

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, BS 5155, ISO 5752.

Flange Drilling: ANSI B 16.1, BS4504, DIN PN 10 / PN 16, JIS 5K, 10K, 16K.

Test: API 598.

|

Working Pressure |

PN10 / PN16 |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

|

Parts |

Materials |

|

Body |

Cast iron, ductile iron, carbon steel, stainless steel |

|

Disc |

Nickel ductile iron / Al bronze / Stainless steel |

|

Seat |

EPDM / NBR / VITON / PTFE |

|

Stem |

Stainless steel / Carbon steel |

|

Bushing |

PTFE |

|

“O” ring |

PTFE |

|

Worm gearbox |

Cast iron / Ductile iron |

The product is used for throttling or shutting off the flow of corrosive or non corrosive gased, liquids and semi liquid. It can be installed in any selected position in pipelines in the industries of petroleum processing, chemicals, food, medicine, textile, paper making, hydroelectricity engineering, building, water supply and sewage, metallurgy, energy engineering as well as light industry.

Product detail pictures:

Related Product Guide:

Antivaccine cardiologist Jack Wolfson and the resurrection of false balance about vaccines…again! | Slide Gate Valve

New U.S. Sales Manager for Lorenz : Plastics Technology | Flange Spring No Return Check Valve

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for OEM/ODM China Gas Butterfly Valve - Motorised metal seated butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Adelaide, Karachi, Suriname, Insisting over the high-quality generation line management and prospects guide provider, we have made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We're ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.