Special Design for Duckbill Check Valve Prices - Electric actuator resilent wafer butterfly valve – Jinbin Valve

Special Design for Duckbill Check Valve Prices - Electric actuator resilent wafer butterfly valve – Jinbin Valve Detail:

Electric Operated Wafer Butterfly Valve

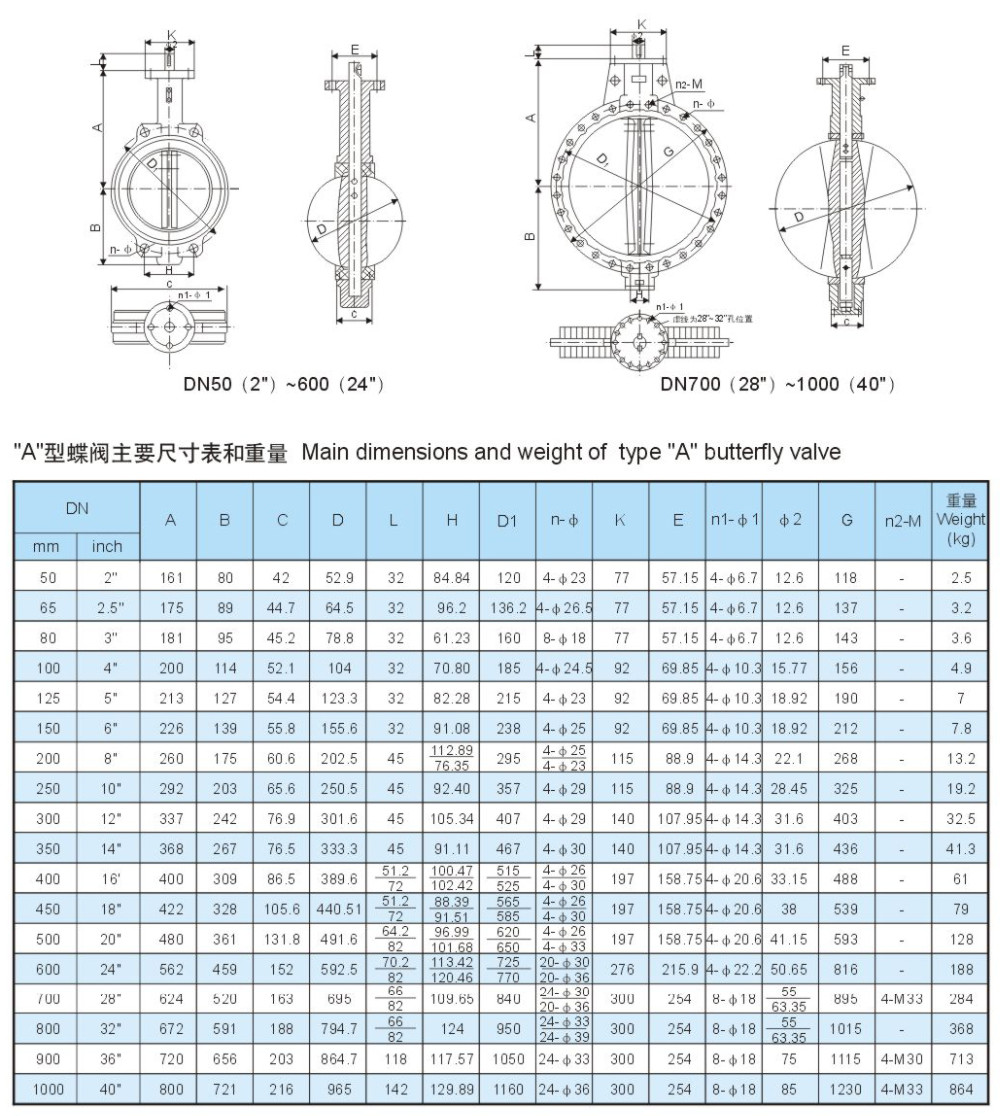

Size: 2”-24” / 50mm – 600 mm

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, ISO 5752, BS EN 558, BS 5155, MS SP-67.

Flange Drilling: ANSI B 16.1, BS EN 1092, DIN 2501 PN 10/16, BS 10 Table E, JIS B2212/2213 5K, 10K, 16K.

Test: API 598.

|

Working Pressure |

PN10 / PN16 |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

|

Parts |

Materials |

|

Body |

Cast iron, ductile iron, carbon steel, stainless steel |

|

Disc |

Nickel ductile iron / Al bronze / Stainless steel |

|

Seat |

EPDM / NBR / VITON / PTFE |

|

Stem |

Stainless steel / Carbon steel |

|

Bushing |

PTFE |

|

“O” ring |

PTFE |

Technical data:

The product is used for throttling or shutting off the flow of corrosive or non corrosive gased, liquids and semi liquid. It can be installed in any selected position in pipelines in the industries of petroleum processing, chemicals, food, medicine, textile, paper making, hydroelectricity engineering, building, water supply and sewage, metallurgy, energy engineering as well as light industry.

Product detail pictures:

Related Product Guide:

DIARY-U.S. refinery operations-Phillips 66 Reports Process Unit Upset At Wood River, Ill. Refinery | | Grooved Butterfly Valve

Specialized Epic 2018: Farewell FSR Hello Single Pivot | Slide Gate Valve

In the past few years, our business absorbed and digested advanced technologies both equally at home and abroad. In the meantime, our company staffs a group of experts devoted to your advancement of Special Design for Duckbill Check Valve Prices - Electric actuator resilent wafer butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Iran, Irish, Norwegian, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products and solutions have been exported to more than 15 countries in the world and have been widely used by customers.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.