Top Suppliers Rising Stem Gate Globe Valve - 200X cast iron Pressure reducing valve – Jinbin Valve

Top Suppliers Rising Stem Gate Globe Valve - 200X cast iron Pressure reducing valve – Jinbin Valve Detail:

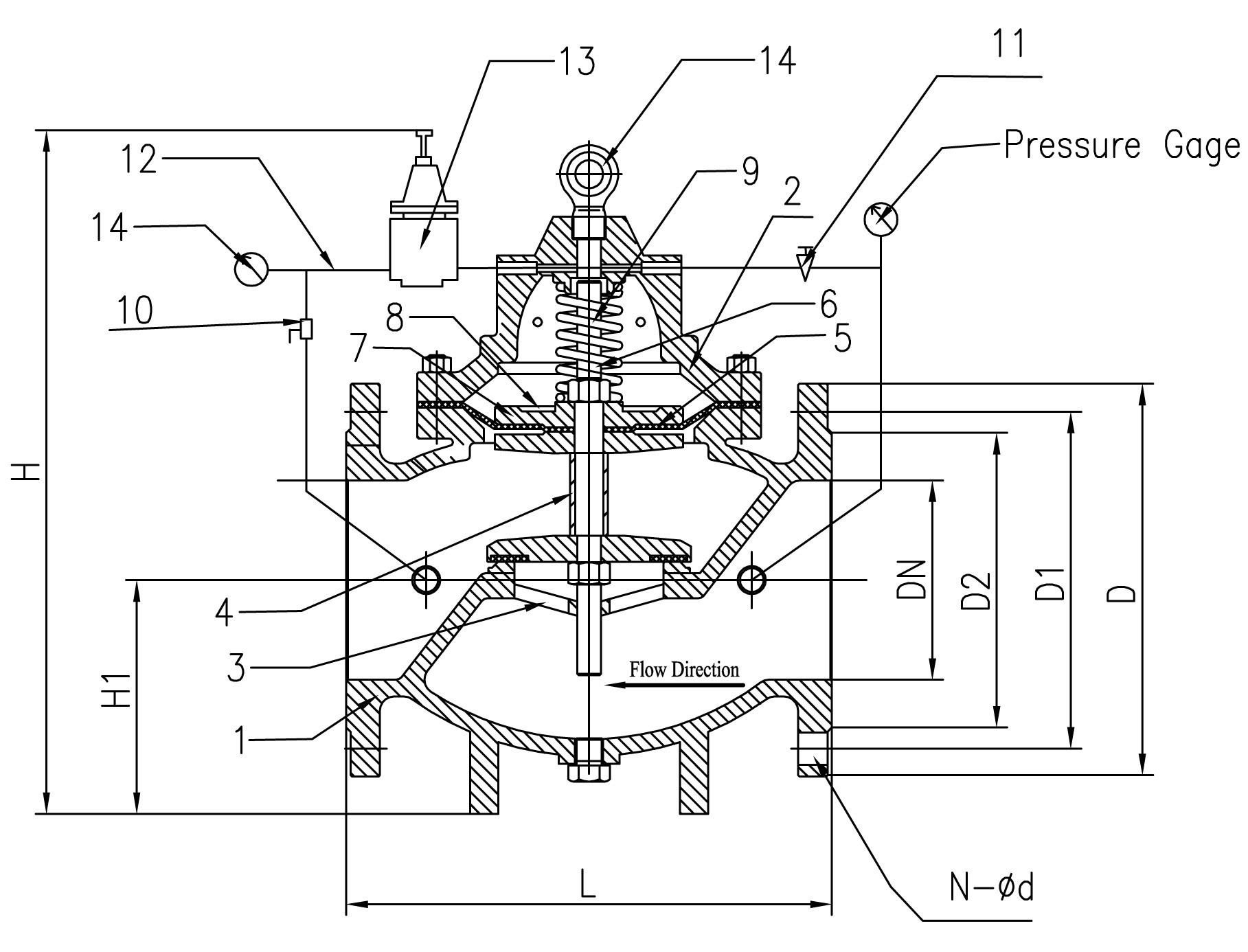

200X cast iron pressure reducing valve

200X pressure reducing valves automatically

reduce a higher inlet pressure to a steady lower downstream pressure, regardless of chaning flow rate and varying inlet pressure.

This valve is an accurate, pilot-operated regulator capable of holding down steam pressure to a re-determined limit. When downstream pressure exceeds the pressure setting of the control pilot, the main valve and pilot valve close drip-tight.

Size: DN 50 – DN 700

Flange drilling is suitable for BS EN1092-2 PN10/16.

Epoxy fusion coating.

|

Working Pressure |

10 bar |

16 bar |

|

Testing Pressure |

Shell: 15 bars; Seat: 11 bar. |

Shell: 24bars; Seat: 17.6 bar. |

|

Working Temperature |

10°C to 120°C |

|

|

Suitable Media |

Water |

|

|

No. |

Part |

Material |

|

1 |

Body |

Ductile iron |

|

2 |

Bonnet |

Ductile iron |

|

3 |

Seat |

Brass |

|

4 |

Wedge coating |

EPDM / NBR |

|

5 |

Disc |

Ductile iron+NBR |

|

6 |

Stem |

(2 Cr13) /20 Cr13 |

|

7 |

Plug Nut |

Brass / Stainless steel |

|

8 |

Pipe |

Brass / Stainless steel |

|

9 |

Ball/Needle/Pilot |

Brass / Stainless steel |

If need the drawing details, please feel free to contact.

1. This valve adjust and maintain the maximum flow rate in outlet regardness of the change of pressure in upstream or dowenstream.

2. This kind of valve is used to adjust the flow pipe from the pump or irrigation system flow, or the flow from main pipeline to the secondary pipe system.

Product detail pictures:

Related Product Guide:

Demand for Cryogenic Valve Increasing due to Growing Offshore and Inland Transportation of Gases | Grooved Butterfly Valve

Emily Greer: “New stores are changing the expectation that only Steam matters” | Rising Stem Type Gate Valve

We have quite a few great team customers very good at internet marketing, QC, and dealing with kinds of troublesome trouble while in the output approach for Top Suppliers Rising Stem Gate Globe Valve - 200X cast iron Pressure reducing valve – Jinbin Valve , The product will supply to all over the world, such as: Canada, Lisbon, Belgium, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.