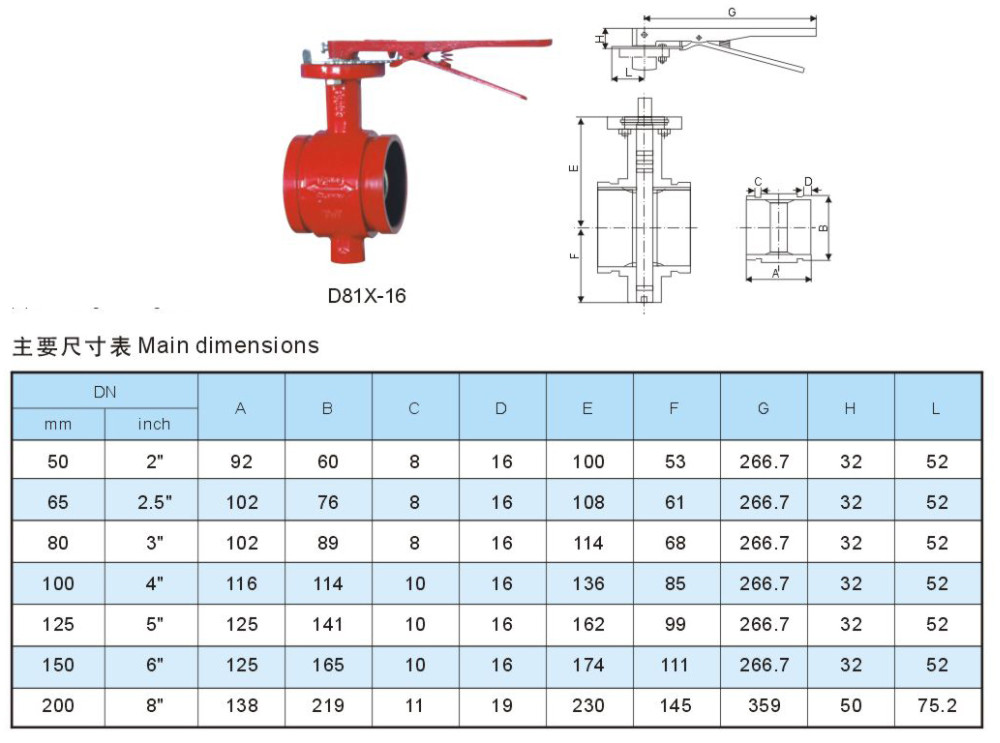

Good quality Metal Sluice Gate Valve - Grooved fire protection butterfly valve – Jinbin Valve

Good quality Metal Sluice Gate Valve - Grooved fire protection butterfly valve – Jinbin Valve Detail:

Grooved end fire protection butterfly valve

Size: 2”-12”/ 50mm –300 mm

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, DIN 3202 k1, ISO 5752, BS 5155, MSS SP-67.

Flange Drilling: ANSI B 16.1, BS4504, DIN PN 10 / PN 16.

Test: API 598.

Epoxy fusion coating.

Different lever operator.

|

Working Pressure |

10 bar / 16 bar |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

|

Parts |

Materials |

|

Body |

Cast iron / Ductile iron |

|

Disc |

Nickel ductile iron / Al bronze / Stainless steel |

|

Seat |

EPDM / NBR / VITON / PTFE |

|

Stem |

Stainless steel / Carbon steel |

|

Bushing |

PTFE |

|

“O” ring |

PTFE |

|

Pin |

Stainless steel |

|

Key |

Stainless steel |

Technical data:

Structure and application:

Fire butterfly groove between the United States and Germany are the introduction of similar design and manufacture of advanced products and a series of new connection valves.It has installed express,simple,simple,safe,reliable,not subject to restrictions on the installation site,piping and valves to facilities maintenance,noise and vibration have a certain perspective of the scope has to overcome the pipelines to connect the different axis arising from poor imitation to solve the temperature difference have advantage.

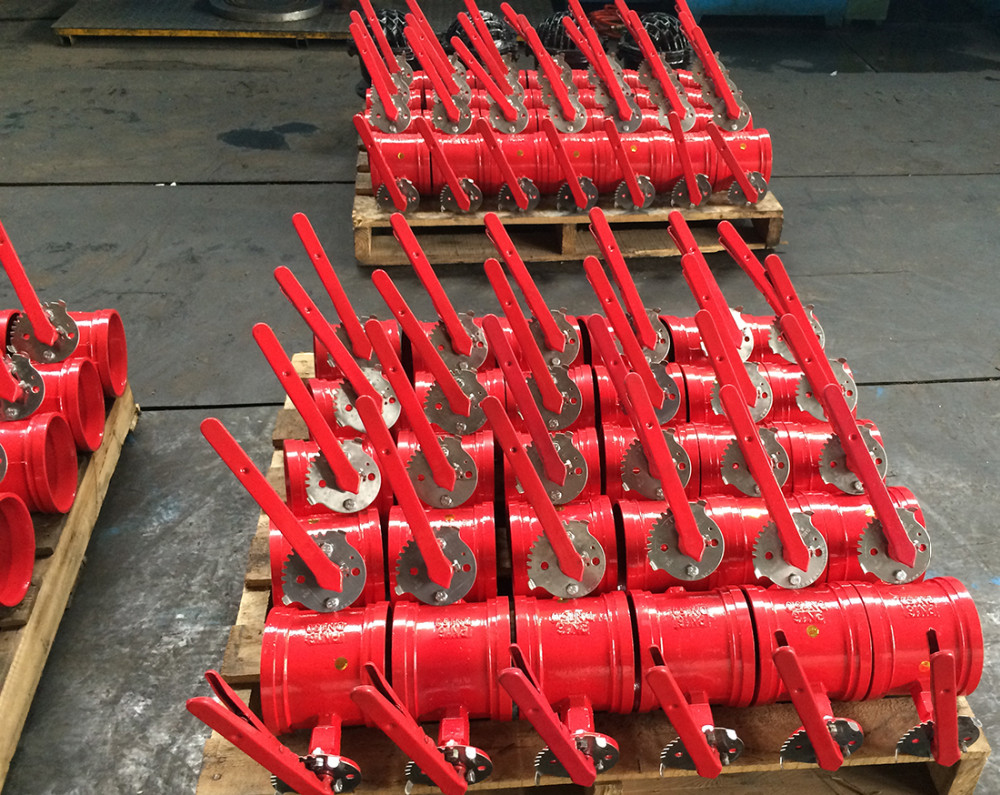

Product detail pictures:

Related Product Guide:

Specialized Epic 2018: Farewell FSR Hello Single Pivot | Check Valve Dn100

Demand for Cryogenic Valve Increasing due to Growing Offshore and Inland Transportation of Gases | Check Valve Dn100

Well-run equipment, specialist income crew, and better after-sales services; We're also a unified major family, anyone stay with the organization value "unification, determination, tolerance" for Good quality Metal Sluice Gate Valve - Grooved fire protection butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Sierra Leone, Islamabad, Burundi, We've been adhering to the philosophy of "attracting customers with the best items and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.