The traditional dust gas butterfly valve does not adopt the inclined installation mode of disc plate, which leads to dust accumulation, increases the valve opening and closing resistance, and even affects the normal opening and closing; In addition, due to the traditional dust gas butterfly valve is often manual, low degree of automation, control and operation is very inconvenient.

In view of the shortcomings of the above-mentioned dust gas butterfly valve, we provides a new type of dust gas butterfly valve. In order to achieve the above purpose, the pneumatic inclined plate dust gas butterfly valve of the utility model comprises a valve body and a valve rod. A disc plate closed in an inclined manner is arranged in the valve body, and the disc plate is connected with the valve rod. The valve body is provided with a mechanical device and a pneumatic device for opening and closing the disc plate through the mechanical device. The beneficial effect of the utility model is that the opening and closing resistance of the valve is reduced, the automation degree is greatly improved, and the utility model is conducive to popularization and application.

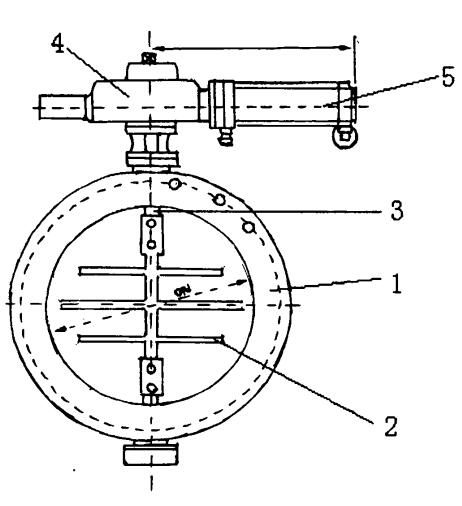

figure 1

figure 2

The specific structure and implementation principle are explained according to figure 1 and Figure 2

The utility model relates to a pneumatic inclined plate dust gas butterfly valve, which comprises a valve body (1) and a valve stem (3). The utility model is characterized in that the valve body (1) is internally provided with a disc plate (2) which is closed in an inclined manner, and the disc plate (2) is connected with the valve stem (3).

The pneumatic plate dust air butterfly valve is characterized in that the valve body (1) is provided with a mechanical device (4) and a pneumatic device (5) for opening and closing the disc plate (2) through the mechanical device (4).

Post time: Jul-08-2021