Hydraulic controlled slow closing check butterfly valve is an advanced pipeline control equipment at home and abroad. It is mainly installed at the turbine inlet of hydropower station and used as turbine inlet valve; Or installed in water conservancy, electric power, water supply and drainage pump outlet, instead of check valve and gate valve. When working, the valve cooperates with the main engine of the pipeline, according to the principle of hydraulic transition process, and through the preset opening and closing procedures, it can realize the reliable cut-off of the pipeline, effectively eliminate the water hammer in the pipeline, and play a role in protecting the safety of the pipeline system.

Working principle

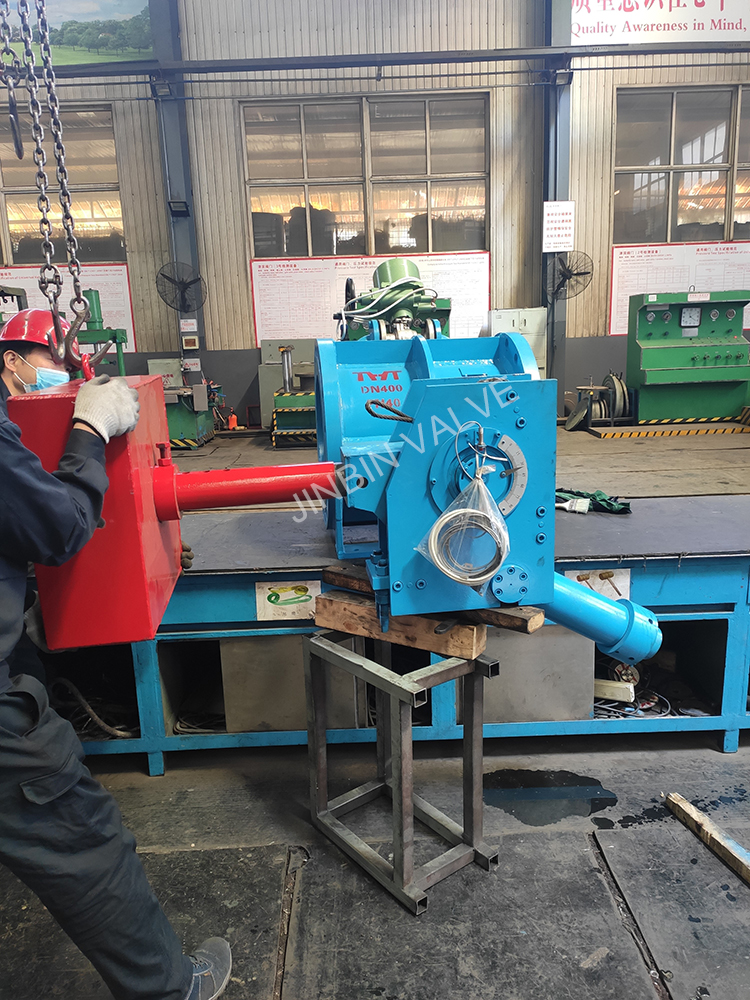

The reserved closing energy of heavy hammer hydraulic control slow closing check butterfly valve is heavy hammer potential energy, which is divided into heavy hammer automatic pressure maintaining hydraulic control slow closing check butterfly valve (hereinafter referred to as heavy hammer pressure maintaining type) and locking heavy hammer automatic pressure maintaining hydraulic control slow closing check butterfly valve (hereinafter referred to as heavy hammer locking type). The service conditions mainly include centrifugal pump condition, axial flow pump condition and turbine condition.

Working condition of centrifugal pump with valve opening (including centrifugal mixed flow pump): start the pump first, and open the valve after delaying the scheduled time.

Working condition of open valve axial flow pump (including axial mixed flow pump): open the pump valve at the same time, or open the valve to a certain angle first, and then start the pump.

Working condition of valve opening turbine: first open the bypass valve to balance the pressure, then open the valve, and then open the turbine.

It is generally required to close the valve at the same time of shutdown or power failure under various working conditions.

The basic electro-hydraulic working principle is as follows:

When opening the valve, the solenoid valve reverses, the oil pump starts, and the hydraulic oil enters the oil cylinder through the flow control valve and high-pressure hose to push the piston and drive the lever connected with it to lift the heavy hammer to open the valve. After the valve is opened in place, the automatic pressure maintaining system starts; The motor continues to charge the accumulator. When the pressure reaches the high pressure set point, the oil pump stops. The valve opening time can be adjusted by rotating the handwheel of the flow control valve, and the adjustment range is 10 ~ 90 seconds.

When the system leaks and the pressure drops to the low pressure set point, the oil pump motor starts automatically and stops after reaching the high pressure set point.

When closing the valve, the solenoid valve reverses, the pressure oil in the oil cylinder returns to the oil tank through the fast and slow joint flow valve, high-pressure hose and solenoid valve, the heavy hammer falls down, and the connecting rod drives the butterfly plate to rotate to close the valve, so as to quickly cut off most of the water flow about 70% of the previous stroke; The latter 30% of the stroke is closed slowly. The angle of fast and slow closing and the buffer time of each stage can be adjusted according to the actual working conditions of the pipeline to effectively eliminate the water hammer in the pipeline; The adjustment time is 2 seconds to 25 seconds for fast closing and 6 seconds to 90 seconds for slow closing.

In the process of opening and closing, the valve can be stopped at any middle position by the stop button. Stop action is mainly used for system debugging.

Manual pump is mainly used for system debugging. When there is no electricity or the oil pump can not work normally, shaking the manual pump can also complete the opening of the valve and the pressure maintaining of the system. Open the normally closed stop valve, under the action of hammer potential energy and hydrodynamic torque, the connecting rod drives the butterfly plate to rotate to close the valve.

Post time: May-12-2021