Ivalve yejethi enomgongxo DN1500

Umngxuma Jet Valve

Ivalve yejethi enomgongxo luhlobo lwesivalo esisetyenziswa kwiinkqubo zokulawula ulwelo. Le valve yenzelwe ukuba ibe nomngxuma okanye umngxuma embindini wayo, evumela ulwelo ukuba ludlule kuyo.

Ivalve yejethi enomgongxo luhlobo lwesivalo esisetyenziswa kwiinkqubo zokulawula ulwelo. Le valve yenzelwe ukuba ibe nomngxuma okanye umngxuma embindini wayo, evumela ulwelo ukuba ludlule kuyo. Isetyenziswa ngokuqhelekileyo kwizicelo apho isantya esiphezulu kunye nokulawulwa kolwalathiso lwe-fluid kubalulekile. Ivalve yejethi enomgongxo idla ngokuba ngumzimba onendawo yokungena kunye nephumayo, kunye necwecwe elishukumayo okanye idiski elawula ukuhamba kolwelo. Xa ivalve ikwindawo evaliweyo, i-orifice ivimba ukuhamba kolwelo. Njengoko ivalve ivulwa ngokususa i-orifice kude nesihlalo, ulwelo lunokudlula kwiziko elinomngxuma kwaye luphume ngokuphuma.

Iivalvu zejethi eziHollow zihlala zisetyenziswa kwidama lamanzi, kunye nokuveliswa kwamandla. Ziluncedo ngokukhethekileyo ekulawuleni uxinzelelo oluphezulu okanye ukuhamba kwesantya esiphezulu, apho ulawulo oluchanekileyo kunye nokusebenza ngokufanelekileyo kuyimfuneko. Uyilo kunye nezinto ezisetyenziselwa iivalve zejethi ezingenanto zingahluka ngokuxhomekeke kwisicelo esithile kunye nohlobo lolwelo olulawulwayo. Izinto ezifana noxinzelelo, ubushushu, kunye nokuhambelana kweekhemikhali kufuneka ziqwalaselwe xa kukhethwa i-valve yejethi engenanto yenkqubo ethile. Ukugcinwa rhoqo kunye nokuhlolwa kubalulekile ukuqinisekisa ukusebenza ngokufanelekileyo kwezi zivalo kunye nokuthintela nakuphi na ukuvuza okanye ukungaphumeleli.

Iivalvu zethu zejethi ezinemingxuma zibonakalise ukusebenza kwazo okuphezulu kwizityalo zamandla ombane ophehlwa ngamanzi kunye namadama okunkcenkceshela. Baqinisekisa ukukhutshwa kwamanzi okulawulwayo nokuhambelana nokusingqongileyo nokuba kungaphandle okanye kumatanki angaphantsi kwamanzi. Amanzi nawo atyetyiswe ngeoksijini kwangaxeshanye. Ukwakhiwa kwensimbi ephezulu ye-valve ye-jet-jet edibeneyo kunye nokutywinwa kwe-elastic / metallic kwenza ukuchithwa kwamandla ngaphandle kwe-cavitation.

-Iimpawu zoYilo-

◆Ekufakweni kwedama, iivalvu zolawulo ezinjengeeHollow jet valves zifakwa emva kweevalve zebhabhathane kwicala lokuphuma. Ezi zivalo zihlala zisebenza njengokulawula ukuhamba okanye iivalvu zokulawula. Iivalvu zejethi ezingcwele eziyilelwe ukwenza ulawulo okanye ukulawula.

◆ukusebenza kwisixokelelwano sonikezelo lwamanzi ngaphandle kokungcangcazela njengokuvulwa kwevalvu.

-Iinzuzo-

◆Uhlengahlengiso oluchanekileyo

◆ Akukho cavitation

◆Akukho kungcangcazela

◆ Ukusebenza ngezandla kufuna amandla amancinci. Nokuba ithini na imeko yepiston, amandla afunekayo ukuhambisa ipiston egqithileyo evuleke kakuhle kwaye ivaliwe iyafana.

◆Ngenxa yokukhuphela emoyeni akukho nobangela wesiphithiphithi kwaye akukho mfuneko yokufakela ihamile yokuthintela amanzi kumazantsi omlambo.

◆Ukugcinwa lula

● Umkhumbi wokuqhuba: Isetyenziswa ngesandla/Eyenziwe nguMbane

● Isiphelo seFlange: EN1092-1 PN10/16, ASME B16.5

● Uvavanyo kunye nokuhlolwa: EN12266, ISO5208D

●Imidiya yolwelo: Amanzi

●Ixesha Lokusebenza: ≤70℃

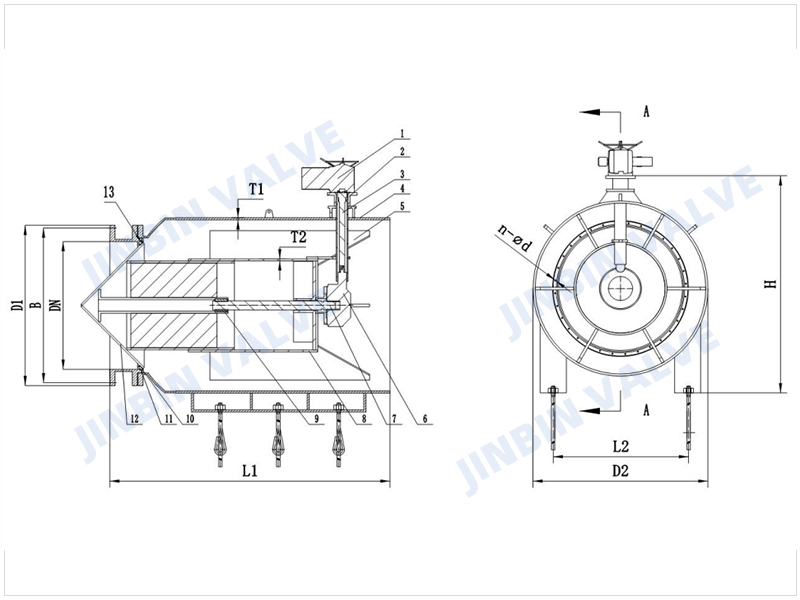

●Amacandelo aphambili kunye neMathiriyeli

| No | Inkcazo | Izinto eziphathekayo |

| 1 | I-activator yombane | INdibano |

| 2 | Idyokhwe | Intsimbi yekhabhoni |

| 3 | Umphini | I-ASTM SS420 |

| 4 | Umzimba | Intsimbi yekhabhoni |

| 5 | Ukunyanzela kwakhona ubambo | Intsimbi yekhabhoni |

| 6 | Isixhobo esinamandla | INdibano |

| 7 | Ukuqhuba shaft | SS420 |

| 8 | Umzimba wokuvala | Intsimbi yekhabhoni |

| 9 | Nut | Al.Bz okanye ubhedu |

| 10 | Umsesane wokugcina | Intsimbi yekhabhoni okanye insimbi engenasici |

| 11 | Umsesane wokuvala isivalo | NBR/EPDM/SS304+Graphite |

| 12 | Ikhowuni yokuvala | Intsimbi yekhabhoni |

| 13 | Umsesane wesitulo somzimba | Welded steel stainless |

●Idatha yoMda

| DN(mm) | L1(mm) | D1(mm) | B(mm) | d | n | D2(mm) | L2(mm) | Wgt(kg) |

| 400 | 950 | 565 | 515 | M24 | 16 | 580 | 490 | 1460 |

| 600 | 1250 | 780 | 725 | M27 | 20 | 870 | 735 | 2320 |

| 800 | 1650 | 1015 | 950 | M30 | 24 | 1160 | 980 | 3330 |

| 1000 | 2050 | 1230 | 1160 | M33 | 28 | 1450 | 1225 | 4540 |

| 1200 | 2450 | 1455 | 1380 | M36 | 32 | 1740 | 1470 | 6000 |

| 1500 | 3050 | 1795 | 1705 | M45 | 40 | 2175 | 1840 | 8700 |

| 1800 | 3650 | 2115 | 2020 | M45 | 44 | 2610 | 2210 | 1230 |